Gravel vs. Concrete Driveway – Which is Better?

For the longest time, homeowners have had few options when it comes to driveways. You’ve got your typical asphalt driveway, concrete driveways, dirt driveways, and basic gravel driveways. These driveways all have their advantages and disadvantages; homeowners have typically had to pick one and live with the results.

There are new options popping up on the market now, however. Gravel driveways, in particular, have seen massive improvements in the technology used to implement them and hold them in place.

In case you’re looking for an alternative to the average concrete driveway, let’s take a look at how modern gravel driveways stack up against concrete, and which one you should choose for your home.

Concrete Driveways are Solid, Yet Flawed

People enjoy concrete driveways when they are first installed because of the smooth surface they provide while driving on them. As they age, however, functional and aesthetic issues may arise. Over time your driveway will likely develop cracks, as it settles the way many home foundations do. Stains show up. And in wet areas, concrete contributes to localized flooding and water around your foundation, in your yard or in your home.

If your concrete driveway was to settle or break apart due to movement beneath the ground over time, you would likely develop low spots. These low spots not only ruin the smooth drive that concrete provides, but they can also wreak havoc on your lawn and home if you have a significant amount of rain.

Concrete driveways provide no outlet for rainwater, which means it’s either going to pool up in your driveway or drain off to the sides where it could end up pooling around your home or flood-prone areas in your home.

In addition to this, oil spills and other motor vehicle liquids do not wash off of concrete driveways easily. You’ll usually need a special concrete cleaning product to get them out unless you want to live with noticeable stains all over your concrete driveway.

Another downside to installing a concrete driveway is that you’ll have to have it done by professionals unless you happen to have all the right concrete pouring equipment laying around. They have almost zero DIY value compared to other options associated with gravel.

“Concrete driveways are more prone to gradual damage from the elements. Aside from that, depending on how it was built, with improper compacted subgrade or bad placement it won’t last long and you need to frequently patch or fill it.”~ Chuck Waltman, Houston Home Remodeler

Gravel Driveways with Plastic Permeable Pavers Are a Major Upgrade

Regular gravel driveways are not without their flaws either. The gravel is usually loose and displaced easily, leading to bare spots and ruts in your driveway. But, with a paver system like the ones offered by TRUEGRID, these issues can be all but eliminated.

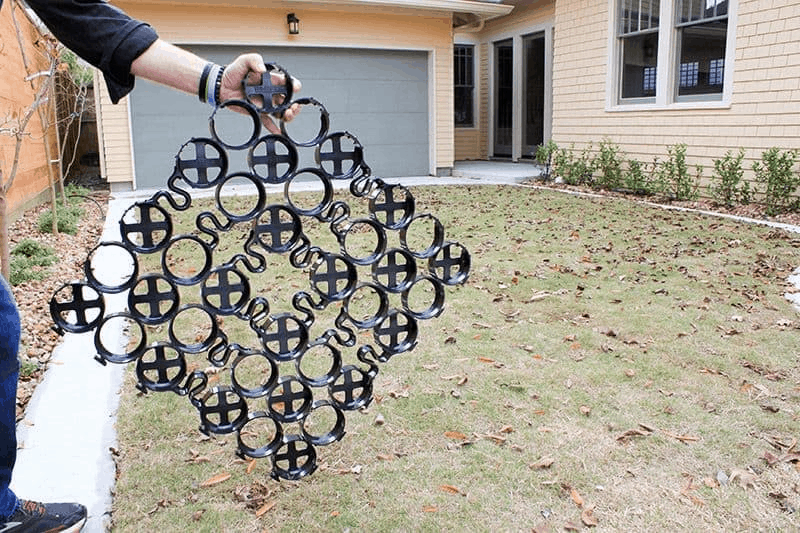

TRUEGRID pavers are permeable, durable, lego-like grids that you can easily install yourself. They are perfect for holding gravel in place and are designed to handle heavy traffic over long periods of time. No mud, no ruts, no gravel spreading or loss. No maintenance. No cracks or water ponding as they provide added drainage. They don’t require any special equipment to install, and you can even use the installation of them as an opportunity to get some quality time with your family on a DIY project.

Another selling point for these pavers in the concrete vs. gravel driveway debate is that spills and stains just don’t pose any problems for them. Any spills from auto liquids or other types of liquid will drain directly through the gravel and into the soil where they are naturally filtered via bio-remediation.

When it comes to environmental-friendliness, gravel driveways with permeable pavers are hard to beat. Not only do they provide a safe avenue for a harmful liquid to drain away once spilled, but they’re also made from HI-IMPACT recycled polymer, meaning they are sourced via a method that actually has a positive impact on the environment, rather than a negative impact.

Choosing Between a Gravel or Concrete Driveway is Not Difficult Once You Know the Facts

The fact of the matter is that there are upsides to both gravel driveway with pavers and basic concrete driveways. There are, however, more advantages (and less negative aspects) to having a gravel driveway with pavers installed.

Not only will they last much longer than a concrete driveway when properly maintained, but they come with a whole host of other benefits for you, your family, and the environment. Auto spills happen to almost everybody, but in a gravel driveway with pavers, they simply disappear into the soil where they can be safely filtered away by Mother Nature.

Gravel driveways with pavers won’t develop bare spots, cracks, potholes, or other unsightly blemishes. They add drainage and flood protection. They are cooler in the summer heat and de-ice faster in the winter. They are also made from environmentally friendly material and can help prevent your home from being damaged due to flooding in your driveway.

In addition, they can also provide you an opportunity to complete a simple and easy DIY project with your family. The benefits of having your children help build a part of your home are immeasurable, and it will give them a small sense of pride.

All in all, choosing a gravel vs. concrete driveway shouldn’t be too hard of a choice once you know the facts. If you value the environment, your family, and the health of your home, it should be obvious to you what the better option is.

option for the base layer of a gravel driveway is item #4. Item #4 is comprised of sand, dirt, and golf ball-sized stones. This type of gravel is available in a few different variations including recycled item # 4, which is made up of recycled stones, brick, blacktop, concrete, and rock.

There is also quarry item # 4, or crushed limestone, gray item # 4 which appears dark grey in color, and crushed bluestone item #4. Crushed bluestone item #4 is usually found in municipal driveways, though.

The middle layer of a gravel driveway features stones closer to golf ball size, with #57 stone being the prominent type of gravel. Otherwise known simply as crushed gravel, #57 stone also helps promote drainage.

5 Types of The Best Surface Gravel for Driveaway

There isn’t a lot of variety for the bottom layers of a gravel driveway, however, there are more options when it comes to finding the best gravel for driveway surfaces. Among the other options are crushed stone #411, quarry process, pea gravel, jersey shore gravel, marble chips, and river rock. These are the best options for driveway surfaces gravel, because they are small stones combined with rock dust, which makes a more solid driving surface.

1. Crushed Stone #411

It is crushed up #57 stone combined with rock dust. This mixture is able to handle moderate traffic from heavy vehicles.

2. Quarry Process

It is also called “crusher run” and works well for the surface of both driveways and walkways. It’s made from stone dust fines and crushed stone.

The stone dust will settle and become compact to create a semisolid surface that is smooth. It is important that you know that this type of surface gravel needs to be sloped towards the sides of your driveway for better drainage.

3. Pea Gravel

Pea gravel is popular gravel for driveway aesthetics. It’s made up of round, small stones that can come in many different colors. This type of gravel will easily migrate and spread under the weight of vehicles, though, and needs to be stabilized for long-term, maintenance-free usage.

4. Jersey Shore Gravel

It is made of yellow, tan, white, gold, and brownstones and looks quite a bit like sand. It’s similar to pea gravel since it needs borders or stabilizing pavers to prevent it from spreading.

5. Marble Chips

Marble chips are white and they sparkle in the sunlight. They typically cost more than other gravel types but are another favorite when it comes to being the best gravel for driveway aesthetic appeal. This type of gravel also needs a border or stabilization to prevent it from spreading, migrating, and washing away.

6. Blackstar or Blacktrap Rock

A very attractive dark gray gravel, this is an excellent choice as it is angular and locks together. When combined with stabilizing grid paving system, this provides a super durable and beautiful driveway.

A Better Alternative to Typical Gravel Driveways

Some of the aforementioned gravel types require stabilization, but the best way to construct any gravel driveway is by using TRUEGRID permeable pavers to lock in your gravel.

TRUEGRID PRO LITE and PRO PLUS stabilizing pavers simply require fill gravel and surface gravel, although you can use the same type of gravel for both. The fill gravel is poured over the top of a piece of fabric at the bottom of the excavated area where you want your driveway that provides drainage for water and other liquids.

It is then compacted and leveled before TRUEGRID permeable pavers are snapped in place over the surface. Next, your surface gravel of choice is poured over the pavers and locked into place using a heavy roller or vehicle. This weighs the pavers down and locks them securely into place.

The main benefit of using TRUEGRID pavers to build a gravel driveway is that they will keep your gravel in place, eliminating the need for almost any maintenance during the course of your driveway’s lifetime.

A properly installed and maintained TRUEGRID gravel driveway is durable enough to handle all types of vehicle traffic and will last up to 60 years without cracking or breaking down in the sun, rain, or other types of weather like asphalt does.. Choosing the best gravel for driveway usage is only part of the equation.

If you want to build your gravel driveway the maintenance-free way, get in touch with the pavement professionals at TRUEGRID today for a quote.

A parking lot is the workhorse of almost any commercial property. It sees more vehicle traffic, abuse, and overall use than any other part of most brick and mortar locations. There are many types of materials a parking lot might be made out of, but the most common one is asphalt and the second most common is concrete. These two materials have been the popular choice for a while because business owners see them as a good look for their business.

Completely paved solid surfaces (which will last for at least a handful of years) have been the standard for some time, but these types of parking lots come with extensive, built-in costs if you want to keep using them for decades.

In case you weren’t aware of the giant financial burden that maintaining the average parking lot can place on a business owner, let’s go through a comprehensive breakdown of just how much asphalt and concrete parking lots will cost you, as well as some better alternatives which are growing more popular every day.

The Cost to Pave a Parking Lot with Asphalt or Concrete is Enormous

There are many factors that make asphalt and concrete parking lots more expensive to install and maintain. One of these is the actual cost of the materials themselves. Asphalt and concrete are expensive to transport, requiring special vehicles and equipment. Compared to locally-sourced fill materials like gravel, these materials are far more expensive.

Installation costs are another area in which asphalt and concrete will drain your finances. Pouring a quality concrete and/or asphalt pavement is a difficult job, and the base preparation is key. Often contractors cut costs during base preparation which causes these hardscape alternatives to crack or pothole because the base failed or the soil moved or trapped water. Labor costs can be high. Added drainage can be as expensive as the surface itself and municipal code restrictions on impervious surfaces and stormwater detention add hidden costs. To do it right for a headache-free and safe parking area, you better be ready to spend. The professional experience required to install a concrete or asphalt parking lot properly does not come cheaply.

The Cost of Paving Parking Lot Includes Long-Term Maintenance

In addition to the extraordinary costs of installing an asphalt or concrete parking lot, you’ll also need to spend money on maintaining it. These types of lots require a system of drainage piping that can provide rainwater an outlet to the sewer system. The cost of maintaining this drainage system will be yours as well.

Not only that, but you’ll also need to re-paint your parking lot lines somewhat frequently. These lines wear out quickly, and not having easily visible lines in your parking lot could potentially lead to lawsuits should someone crash or get injured in your lot. All of these costs added up will create a massive and ongoing expense that, quite frankly, is unnecessary.

Reduce the Cost to Pave Your Parking Lot with Permeable Pavers

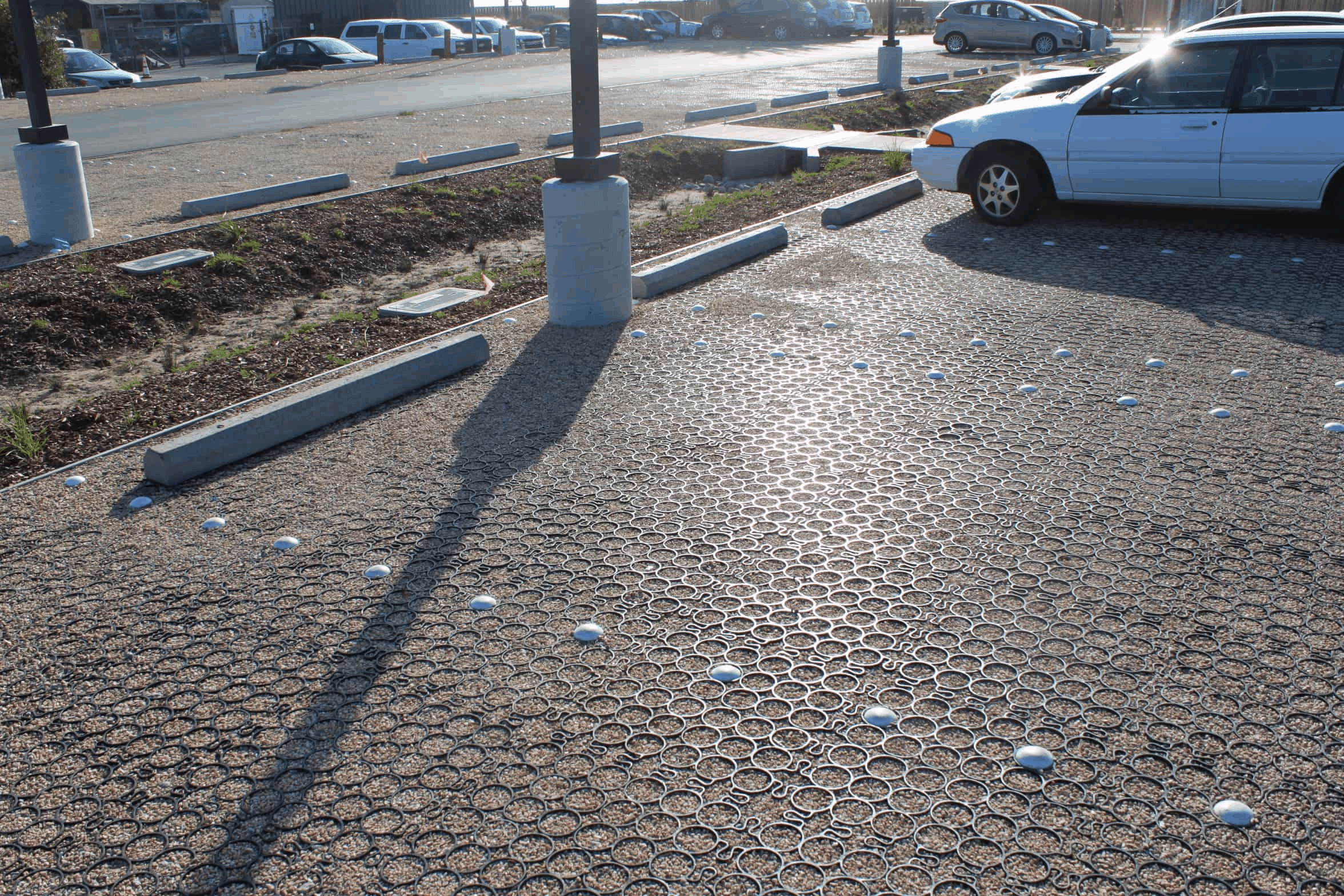

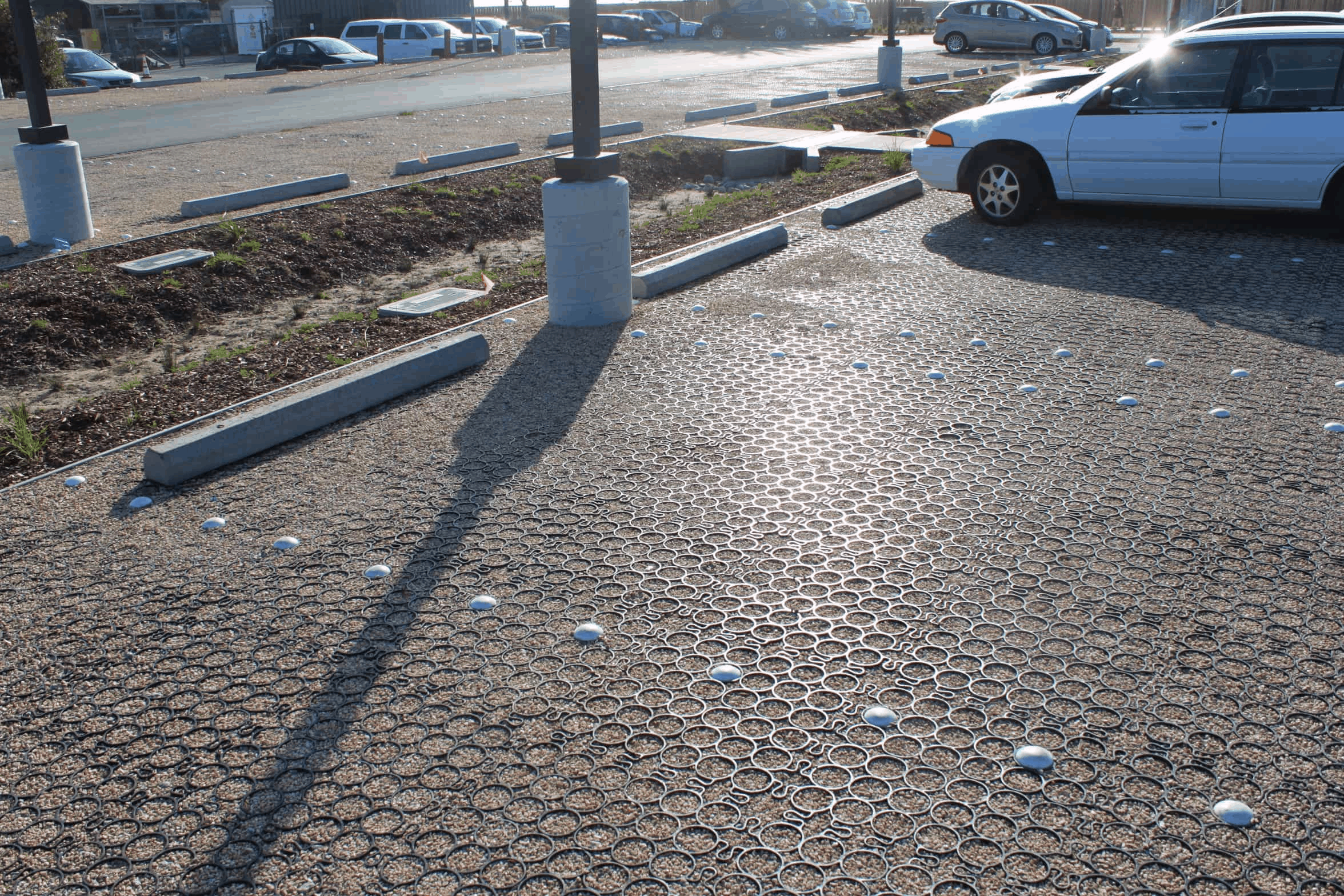

One of the best new options for business owners looking to install a parking lot is permeable pavers. Permeable pavers are interlocking grids made from a highly durable, recycled plastic. These pavers are placed on top of a prepared subsurface as well as a fill material like crushed limestone or gravel. Once locked into place, these pavers create a durable and virtually maintenance-free parking lot that will last for decades to come.

Because the installation process is so simple, the cost of installation is much lower than with asphalt or concrete. There’s no need for a team of expensive professionals working day in and day out to complete a complex parking lot installation. The process is so easy that even unskilled laborers could complete it without issue. Permeable pavers such as the kind offered by TRUEGRID are also much less expensive upfront than asphalt or concrete, and they don’t require nearly as much in the way of maintenance.

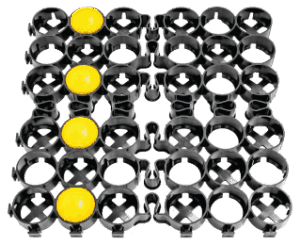

TRUEGRID even offers colored spot markers which you can snap into place to create parking lot lines that will never fade and never require re-painting. Because of the permeability of the paver system, you don’t need to have any drainage installed either. Rainwater and other liquids will simply leak right through the parking lot and into the ground without any problems.

The Benefits of Permeable Pavers are Hard to Overstate

If you’re looking for a parking lot that never develops potholes, never fades or breaks down, and costs much less to install and maintain than traditional concrete or asphalt parking lots, look no further than permeable pavers like the kind that TRUEGRID offers.

Gravel, crushed limestone, or grass parking lots are now much more feasible to work with for business owners, thanks to these pavers. With almost none of the negative aspects of asphalt or concrete and a plethora of benefits including increased safety, higher cost-effectiveness, and more options when it comes to style, it’s all too obvious what the smart choice is when it comes to installing a parking lot in 2019, and beyond.

Asphalt parking lots have long been the standard for commercial businesses of all types. While they have served us better than dirt parking lots or loose gravel parking lots, they still have many faults of their own. With new advances in parking lot technology, there are many more options for business owners now when it comes to what kind of parking lot they want to install.

If you’re a business owner looking to circumvent the variety of problems that can arise with asphalt parking lots, you can greatly benefit from learning about newer types of parking lots that can serve you just as well as asphalt, without any of the downsides.

In case you’ve never heard about grass or gravel parking lots, and the advances in technology surrounding them, here are some facts about parking lot alternatives that will help you make the most informed decision when it comes to upgrading your parking lot.

Parking Lot Alternatives are Needed for Asphalt

Asphalt has served as well up until this point, but the need for new types of parking lots is becoming painfully obvious. Asphalt is terrible in the summer, for instance. When the heat rises during the day, asphalt absorbs a great deal of it, thanks to its black color. This causes the asphalt to heat up and become soft and oily which not only leaves behind a residue, it can also burn the skin of anyone who happens to touch it.

Asphalt also breaks down rather quickly, requiring regular maintenance. You’ll need to fill holes, perform seal coating, and a variety of other procedures on your asphalt parking lot to keep it in decent shape. Even a well-maintained asphalt parking lot will only last around 15 years with a frequent repair. Asphalt is also limited when it comes to style options, with the only color being black and becomes aesthetically uglier with age.

Grass and Gravel – The Best Parking Lot Alternatives

Gravel and grass may not be the first types of parking lots that come to mind when you envision modern parking lot alternatives, but the kind of gravel and grass parking lots we’re talking about aren’t the kind you’re thinking of.

With new advancements in paver technology, there’s never been more to be excited about in terms of gravel and grass parking lots. Products offered by TRUEGRID and other companies now make it more feasible than ever to install them anywhere.

Grass Parking Lots

Grass parking lots have always had a certain natural appeal, but business owners haven’t been able to implement them in high-traffic areas because the grass can’t handle it. Ruts, washed out areas, and other problems are quick to appear in a normal grass parking lot, but with TRUEGRID pavers this isn’t a concern.

These permeable pavers are lightweight and durable, allowing them to keep material like grass and gravel locked in place while providing a quick outlet for water and spills of all types. You never have to worry about them breaking down, becoming cracked, or any other problems that you’ll definitely encounter sooner or later with material like asphalt or concrete.

Gravel Parking Lots

In addition to grass parking lots, you can also install gravel parking lots with the TRUEGRID system. Combined with permeable pavers, gravel makes for an excellent alternative to asphalt. With virtually no maintenance, it can last far longer than asphalt and has a more positive impact on the immediate environment as well.

You won’t have to worry about a deteriorating, broken-down parking lot that’s pooling water and causing navigation issues for drivers or localized flooding if you have a gravel parking lot held in place by permeable pavers. No stepping into ankle deep water when you exit your vehicle because TRUEGRID permeable pavers filled with gravel drain at over 1000 inches per hour.

Gravel makes for one of the best materials to build a parking lot from, thanks to its permeability. The many thousands of rocks can be held together to form a solid surface that holds up under the most intense vehicle traffic, yet still allows liquid to pass through unencumbered.

With this kind of a parking lot setup, you can avoid wasting a giant chunk of money on having to repair and maintain your parking lot. You can also avoid any potential lawsuits, should somebody step in a pothole in your parking lot and get injured.

Why Use Asphalt When There are Better Parking Lot Alternatives?

When you consider the pros and cons of using either a grass or gravel parking lot combined with the TRUEGRID permeable paver system vs. a regular asphalt parking lot, the choice is obvious. Depending on your needs as a business owner, it’s going to be much easier for you financially if you choose a gravel or grass parking lot.

Installed with the TRUEGRID paver system, these parking lot alternatives are more cost-effective and less of a burden to work with. They also provide you more stylistic and natural options as well as preventing any pothole-related catastrophes. All in all, it’s hard to see why you would ever go back to asphalt.

Concrete and asphalt have served us well over the ages. From parking lots to walkways, driveways, sidewalks, intermediate areas, and more, both asphalt and concrete have gotten the job done when it comes to providing solid surfaces for us to walk and drive on.

Water pooling and runoff have also been an issue with these materials, however. Flooding from impervious surfaces is wreaking havoc contributing to billions of property damage and even deaths. Porous concrete and pervious asphalt were invented to help reduce the costly consequences of impervious surfaces.

Videos of porous asphalt absorbing water have gone viral. Everyone knows that surfaces that absorb water instead of creating runoff and flooding are needed. The problem is- this porosity and ability to absorb water is very short-lived and super expensive. You don’t see that in the video.

Porous concrete and asphalt while better than traditional hardscape aren’t without their own issues, though. In fact, some of the potential problems you might face with porous asphalt or concrete could end up being so serious that it costs you thousands in repairs or remodeling. Many people still aren’t aware of the potential pitfalls of something like a porous concrete driveway or porous asphalt, however.

In order to get you up to speed on the potential issues with these materials, let’s go over how they work, what problems you might face, and what might be a better alternative to porous asphalt or concrete.

A Porous Concrete Driveway Won’t Be Perfect

Obviously, water runoff and collection is a big deal, this is why permeable materials for things like driveways and sidewalks were invented. Porous concrete or asphalt surfaces are made up of a coarse aggregate that is coated in mortar or cement paste. This creates a structure in which there are countless pathways for water to trickle through the surface and down into a collection area or directly into the soil. In theory, this is a great idea. But, there are a variety of ways in which this system can fail you.

First, clogging is the main issue with porous concrete and asphalt. If you’ve got stormwater running over and through your permeable asphalt surface, it’s going to carry particles of dirt and debris that will clog up the interior of a once permeable surface. The pore size is very small by necessity and within a few months, the formerly porous asphalt or concrete will begin to pool water and becomes essentially impervious. This clogging doesn’t allow water to pass through as quickly and will lead to the collection of water inside the permeable surface.

Once clogging has caused water to collect in areas where it’s not supposed to, porous asphalt and concrete become vulnerable to freeze and thaw cycles. Weaker to begin with than traditional hardscape surfaces due to the high gravel content to create porosity, these surfaces are not durable. These cycles cause water trapped inside them to damage the pavement by expanding and contracting ice causing failure.

A couple of other problems with porous asphalt and concrete include sulfate resistance and abrasion resistance. These surfaces are often vulnerable to soil with high levels of sulfate in them. To avoid the degradation of a permeable surface due to high levels of sulfates, a business owner would have to go the extra mile when installing the surface and make sure to only use cement which is sulfate-resistant.

Abrasion resistance is another area to be concerned about when discussing porous asphalt and concrete. Areas subject to high levels of traffic, turning traffic, or snow plows are of particular concern when it comes to this issue. Because of the porous nature of porous concrete and asphalt, they are not typically very resistant to abrasion. This can lead to surface particles unraveling and becoming loose, would mean the early demise of your porous concrete or asphalt surface, no doubt.

While initial installation may be as much as 50 % more than non-porous pavement, maintenance is often the expense. Frequent specialized industrial vacuuming is required to maintain porosity and surface infiltration capabilities.

Porous Asphalt and Concrete Are Not the Solutions

While permeable surfaces will always be in demand, inferior materials like asphalt and concrete are always going to fall short. If you want a surface that is permeable, yet impervious to abrasion or clogging, you’ll need a different solution.

Permeable pavers from TRUEGRID make an excellent alternative to the materials we’ve just discussed. They are interlocking grids made from highly-durable recycled plastic and feature a variety of benefits that permeable concrete and asphalt do not.

You never have to worry about your pavers getting clogged because they use either gravel or crushed limestone as an aggregate, and the spaces between the aggregate are too large for clogging to become an issue. They continue to absorb rainwater after years of heavy traffic and use at a rate of over 1000 inches per hour. In other words, the TRUEGRID pavement drains instantly for the life of the site.

A gravel-filled permeable pavement surface such as this stops gravel migration. The patented design allows for flexibility to eliminate cracks or potholes but has enough strength to handle any load on the road. Snow plowing is not a problem and residual ice or snow melts faster than on asphalt or concrete. The installation process for permeable pavers is also quicker and more cost-effective than with asphalt or concrete.

Permeable pavers require almost no upkeep or maintenance and will serve you better than either traditional or porous asphalt or concrete would, and for much longer. If you’re in need of a permeable surface solution for a parking lot, sidewalk, driveway, or other surfaces, you should look no further than permeable pavers from companies like TRUEGRID and others.

The durability and versatility of this paver system work well for any paved site from driveways to parking lots. Residential, commercial, and industrial needs can all be met by this innovative new product, allowing business owners to spend less and get more for their money as well.

Creating an area in your business that can handle everything from a toddler’s walk to a large commercial vehicle is a daunting task. Most engineers and architects immediately turn to traditional materials, such as concrete and asphalt. But the same old paving methods are many. These materials may require regular maintenance, cause flooding, pollutant runoff, pothole or crack in extreme weather and are not the most environmentally friendly or aesthetically appealing.

Plastic pavers are rapidly becoming the new paving solution architects, builders, engineers, and even homeowners are turning to. The significant benefits versus traditional concrete pavers, gravel, or asphalt. Businesses and outdoor spaces can take advantage of this technology to completely transform their businesses. Plastic pavers are filled with grass or gravel and create walkable, driveable surfaces that drain quickly and look good. Businesses can benefit from durable, driveable surfaces for their use or for their customers, while garnering support from their communities by creating innovative green spaces.

Why Use Plastic Pavers

Many designers are unaware that new plastic paver systems can be a direct replacement for traditional hardscape and yield a number of benefits over concrete or asphalt. 100% permeability so water is absorbed instantly; stormwater detention under the surface to save land; pollutant filtering of runoff toxins; reduced heat island effect in urban areas creating a cooler site; more green space and a natural aesthetic when the pavers are filled with gravel or grass.

Stormwater runoff is the primary reason that architects and engineers install plastic pavers. Preventing flooding, increasing stormwater detention on a site is critical in the age of extreme weather events. Some plastic paver systems absorb rain at over 1000 inches per hour, preventing flooding, ponding or pooling and reducing the runoff to zero. When used with a clean washed rock base under the pavers stormwater can be retained, stored and released slowly to protect homes and businesses from rising waters. This is a contrast to impervious hardscape surfaces such as asphalt or concrete which cause water to rise, overwhelm city drainage systems and cause billions of dollars of damage and trauma to flood-ravaged communities. Permeable plastic pavers are part of the solution.

Removing pollutants from the stormwater before it recharges aquifers is a huge benefit of plastic systems. By allowing infiltration into the soil, as opposed to runoff of concrete, auto and other pollutants such as hydrogen, nitrogen, phosphorous, and various hydrocarbons are naturally filtered via the bioremediation process. Permeable plastic pavers allowing infiltration and natural filtering can remove up to 90% of pollutants from the water table.

Less drastic temperatures is another benefit of using plastic pavers. In the winter, there will be less ice buildup as any precipitation will seep through the paver. In the summer, there will be no extreme heat on the surface as the fill material will be cooler than concrete or asphalt. This will lead to a safer environment for all.

Aesthetically, plastic pavers allow for many options with different fill materials. Any color gravel or grass. Plastic pavers can be filled with gravel for highly trafficked commercial and industrial parking lots yielding a maintenance-free stabilized parking and driving area. They also can be filled with grass for fire lanes, driveways and light trafficked areas to provide green space and stabilized, strengthened, reinforced grass pavement.

Types of Plastic Pavers

Choosing a plastic paver will have dramatic consequences on the area you are installing it on. There are four different types of plastic pavers that are currently available on the market. They all have different qualities. Engineers and architects should carefully evaluate each type to find the type that will work the best for their case.

Rolled Pavers (also called “Roll Pavers”)

These plastic pavers come in, you guessed it, a large roll. The roll size is typically four feet wide and up to 150 feet long and the pavers are completely flexible.

Rigid Plastic Pavers

These pavers (sometimes also called “Panel Pavers”) come in both connecting and non-connecting varieties. Typically the designs use a honeycomb pattern arranged into a long and large grids rectangular shape. Sections have to be cut off during installation as the standard grid sizes do not fit most applications.

Geocell

These are strips of thin plastic that are connected to form an expandable mesh. Geocells are also known as cellular confinement systems and utilize ultrasonically welded high-density polyethylene (HDPE) strips or novel polymeric alloy (NPA) for their structures.

TRUEGRID

Inspired by LEGO bricks, TRUEGRID plastic pavers are square sections of permeable pavers that click together to cover any shape of area such as a parking lot or driveway. These are made of thicker HDPE which balances rigidity and flexibility.

Pros and Cons of Different Plastic Paver Systems

Rolled Pavers Pros and Cons

Pros of Rolled Pavers

– Typically made from 100% recycled plastic

Cons of Rolled Pavers

– Installation – Rolling out these pavers may seem easy but aligning the rolls and connecting them is most decidedly not easy. Rolled pavers require staking every 3 feet to prevent the flexible rolls from moving and coming up. Another disadvantage in commercial applications is that the rolled pavers are not strong enough to support gravel trucks driving and dumping loads on them during installation. This makes the fill process much longer and labor intensive. Having to move, reposition, and connect large rolls (96 to 600 sq ft each) can be a challenge. The edges of the long, heavy rolls must be aligned perfectly so that the plastic connectors on the edge of one roll can connect the other roll. Once a roll is placed on the ground, it is difficult to move due to the size and weight of the roll. The large size of each roll can also be a disadvantage when fitting the pavers to the paved area.

-Lower Strength: The cell walls in rolled pavers are thinner than other plastic paving systems, therefore the product can buckle under pressure. Rolled pavers do not have any flex joints. When vehicles turn they can easily twist the grid enough where it completely disconnects.

-Stake Installation Required: An installation challenge with rolled pavers is that they have to be staked every 3 feet. That means you and your team are going to spend extra hours and dollars installing this type of plastic paver. The installation process is already rather difficult and adding the extra steps can turn a potential buyer off from the system.

-Clogging: Some rolled plastic pavers have a fabric attached to the bottom of the paver to add strength and stability. This fabric tends to clog very quickly and suddenly the “permeable paver” becomes impermeable.

Rigid Pavers (Non-Connecting Pavers) Pros and Cons

Pros of Rigid Pavers

-Suitable for light-duty grass applications: Rigid plastic pavers have been shown to work for grass-filled applications. Purely foot traffic areas may be the best choice for these type of plastic pavers. There will not be too much force to break any of the connectors that hold the entire structure together.

Cons of Rigid Pavers

-Low Flexibility: Rigid plastic pavers are, unsurprisingly, inflexible. That is an issue if there is any ground variation or slope in the area where you are trying to install the plastic pavers. Low flexibility means these pavers may not hug the ground and portions of the pavers could then crack due to insufficient support underneath.

– Lower torsional strength. These pavers have a low ability to withstand the forces of a twisting load. This problem appears when trucks or cars make turns on these pavers. The torque force of vehicles turning can break the connectors off the edges of these pavers. This can result in the edges of these pavers popping up and then getting pulled or snagged by vehicles, resulting in more damage to the pavers, vehicles, or both.

-Susceptible to Cracking: When the temperature rises and falls throughout the year there is a high chance that the paver will end up cracking. Due to the coefficient of thermal expansion of the material and the stiffness of the overall structure this paver may experience due to temperature and weather changes.

Geocell Pavers Pros and Cons

Pros of Geocell Pavers

– Inexpensive. Because of their lightweight construction (using thin plastic) and collapsible design, Geocell pavers are less expensive than other pavers.

– Suitable for foot traffic or light-duty applications without vehicles where there is little chance of the fill gravel being disturbed.

Cons of Geocell Pavers

-No Compressive or Tensile Strength: One of the biggest issues of geocell plastic pavers is that they have almost zero compressive and tensile strength. The lack of compressive strength means that the gravel fill is bearing nearly all of the load. When the gravel in the geocell pavers is disturbed, the exposed edges of the geocell pavers get crumpled under the weight of vehicles. This leads to durability problems for geocell pavers. The pavers eventually break down and cannot withstand large loads.

-Challenging Installation: Since geocell plastic pavers are made from an expandable mesh, installation requires stakes, clips, anchors, and stake drivers. This increases the overall cost of the plastic paver system and the installation time.

-Long Term Problems: A recurring issue with geocells is their lack of durability. The required lifetime for some surfaces is 20 to 25 years and geocells simply do not last anywhere near that long. Geocell lifetime is measured in months, not years.

TRUEGRID Pavers Pros and Cons

Pros of TRUEGRID Pavers

– Strength: With a compressive strength of over 8,000 psi, there are few pavers that can stand up to TRUEGRID. For reference concrete typically has a compressive strength of 5000 psi for commercial applications. Even the empty grid can easily handle 40-ton gravel trucks during the installation process to speed rock fill.

– Durability. TRUEGRID plastic pavers have a lifetime of 25 to 60 years depending on the application, which is longer than asphalt and as long as concrete. This is one of the main reasons TRUEGRID dominates the commercial and industrial markets for plastic pavers. TRUEGRID was the first and is still the only plastic paver that has been successful in millions of square feet of commercial parking lots and truckyards across the world. That completely overshadows some of the other plastic pavers that are currently on the market.

-Easy Installation: After the surface is prepared, the TRUEGRID pavers can easily be installed with just a small crew. The grid size is also very small compared to other types of plastic pavers. This allows for fewer cuts needed when installing the plastic paver.

-Slopes and Inclines: TRUEGRID has the best of both worlds, strength and flexibility. The grid pavers can be installed on a slope up to 20 degrees without staking and is very accepting of uneven terrain and elevation changes..

Cons of TRUEGRID Pavers

TRUEGRID plastic pavement system, while typically less expensive than concrete, is more expensive than asphalt unless added drainage elements and a detention pond is required.

ADA Compliance

You can have plastic pavers and have an ADA compliant surface. Be sure to choose the right fill and minimize transition heights to be ADA compliant. See manufacturer for guidance.

Checklist for considering plastic pavers

Traffic loads. Is the plastic paver designed for heavy traffic or loads?

☐ Staking. Is staking required?

☐ Maintenance. Will maintenance be minimal?

☐ Stormwater detention. What stormwater detention is needed, and how much detention do the pavers provide?

☐ Strength. What is the compressive strength of the pavers? What is the torsional strength?

☐ Flexibility. Does the paver have flexibility to move with loads and ground movement?

Which is the Best Choice for Your Paving Project

Developers, architects and civil engineers face a critical task.

They need to provide enough parking and surface storage for their projects, but in an environmentally conscious way.

This requires…

-

Urban flooding after heavy rain. Using paving surfaces that rainwater can infiltrate instead of running off

- Using environmentally friendly materials

Traditional paving surfaces such as asphalt and concrete do not allow rainwater to infiltrate into the soil. The result? Urban flooding has become an increasing problem.

Retention ponds can be used to control runoff but take up large areas. For example, a 120,000 square foot parking area could require that 21 percent of the space be reserved for a retention pond. This is a loss of 25,000 square feet of useful space.

Asphalt can also leach toxic chemicals into the water table. Even with the use of retention ponds this can create serious environmental issues.

Two Eco-Friendly Paving Solutions

Two different paving systems can mitigate surface runoff and also use eco-friendly materials and techniques.

Pervious concrete. Also called “permeable pavement” this method uses only coarse aggregate and cement, but with no sand in the mix. This increases both porosity (void space) and permeability (the ability to conduct water). Both aggregate and cement are environmentally inert materials.

Permeable paver grid systems. This second option uses an open, plastic grid made from an inert material such as high-density polyethylene (HDPE). The grid is then filled with a washed angular aggregate. An example of this, TRUEGRID®, is considered the premier permeable grid paver system currently available.

But which is the best choice? Both systems use eco-friendly materials. Both allow rainwater to infiltrate the soil. Let’s compare these two paving solutions.

- Cost

Construction costs can vary, but permeable paver systems typically are 33%-50% below the price of standard concrete construction. Permeable concrete is more expensive than standard concrete, making Permeable Pavers even more economical.

- Ease of Installation

Concrete, whether standard or pervious, needs several days to “cure” once poured. During this time, it must be closely monitored and protected. The process has to be repeated for each individual section poured. You can’t walk or drive on the surface until it has completely cured.

Permeable paver installation is fast. For example, one person can install 1,000 square feet of grid of TRUEGRID pavers per day.

Once the grid is in place…even before the aggregate is installed…you can walk and drive on it. This avoids construction delays.

- Strength

Pervious concrete has an average compressive strength of 2500 psi with a range of 500-4000 psi. Actual strength depends on the specific mix of cement and aggregate…and requires lab testing to confirm.

The compressive strength of aggregate-filled permeable paver systems can exceed pervious concrete. For example, TRUEGRID pavers compressive strength ranges from 6500 psi (residential) to 8000 psi (commercial).

- Ongoing maintenance

Once the pavement or pavers are installed, we need to look at the cost of keeping the surface attractive and usable.

Pervious concrete pavement is not completely maintenance free:

Painted markings require periodic re-painting

These cracks must be repaired to prevent additional damage. Cracks can form due to shifting soil, temperature variations and precipitation.

TRUEGRID systems, however, are virtually maintenance-free:

The HDPE grid flexes using patented S-joints to adapt to shifting substrate. This prevents cracking.

Durable, maintenance-free SuperSpot® markers are inserted into the grid to provide surface markings. SuperSpot color is throughout the material, so the color cannot wear off.

- Infiltration capacity

Water infiltration rates for pervious concrete range from 288-770 inches per hour. For TRUEGRID systems, infiltration typically exceeds 800 inches per hour.

Not only does TRUEGRID exceed the infiltration capacity of pervious concrete, it also exceeds the highest rainfall intensities recorded in most areas of the United States.

- Eco-friendliness

Besides using environmentally inert aggregate for fill, TRUEGRID is manufactured from 100% post-consumer recycled HDPE. This creates an environmentally safe paving surface plus reduces landfill use.

The final analysis

Both TRUEGRID and pervious concrete provide eco-friendly solutions to the surface water issue.

However, TRUEGRID offers several advantages over pervious concrete, including the following:

- Lower cost

- Easier installation

- Greater strength

- Less maintenance

- Higher water infiltration

- Better use of recycled materials

Local and state governments will continue to press for sustainable solutions to combat local flooding and groundwater issues. TRUEGRID provides developers and property owners with an effective, eco-friendly tool to mitigate surface runoff.

For more information on TRUEGRID permeable pavers or to request a quote, visit www.truegridpaver.com

Who’ll Stop the Rain?

There’s a change coming in New Orleans. A paradigm shift from the same ‘ol same ‘ol way of doing things to a better way. New Orleans is the first great American city to take this bold step towards a solution for flooding.

New Orleans is below sea level. Streets, homes and business flood not only during hurricanes but with normal everyday rain events. Impervious concrete and asphalt blanket the city and create flash flood events on a frequent basis.

Storm water too often overwhelms city drainage systems and floods businesses and homes causing damage and distress.

After years of concerted effort, concerned citizens, businesses and local government have put forth new regulations that will help mitigate flooding going forward.

Permeable pavement must be used by law for any new commercial parking lot or paving site. No more impervious concrete or asphalt. Ordinance No. 32,757, effective Sept 5, 2019.

How did this happen? Well it’s been years in the making.

Jay Nix, owner of the iconic Parkway Bakery, home of the world’s best poor boy sandwiches and frequently listed on the annual New York Times America’s best sandwich list, was the first business owner to step up. Jay had a parking lot that needed repair and expansion, flooded frequently hurting his business. (Go check out the place, have a great poor boy sandwich and marvel at Jay’s photos with ex-Presidents, boxers, and stars) He did a Google search and found TRUEGRID, the world’s strongest permeable pavers. In June 2015, Jay installed 30,000 sf of TRUEGRID PRO PLUS in his parking lot along to provide a 100% pervious surface with stormwater detention in the crossection. The lot has absorbed and detained water through storm after storm.

So today we celebrate a paradigm shift. Part of the solution. Concrete and asphalt are no longer allowed in new parking lot construction in the city of New Orleans.

Who’ll stop the rain? Well it’s not going to stop- but it will get absorbed as nature intended in new permeable parking lots going forward. Congratulations to all involved to become the first American city to take this positive step. This is a big deal.