Blacktop vs. Concrete: The Best Material for Driveways and Parking Lots

When it comes to paving areas like parking lots and driveways, two materials usually come to mind, concrete and asphalt. Asphalt, otherwise known as blacktop, is similar to concrete in terms of performance and cost but does differ a bit.

Whether you’re looking to pave a parking lot or you’re wondering if you should install a blacktop or concrete driveway, there are plenty of factors to consider. So, let’s do a complete rundown of how these two paving materials stack up against each other and explore a possible alternative to both as well.

Cost Comparison – Blacktop vs Concrete Driveway

One of the biggest influential factors on your decision will probably be the cost. There are both short-term and long-term costs for asphalt and concrete. Asphalt is cheaper than concrete to install, at about $3 or $4 per square foot. Concrete typically costs at least $6 per square foot to install.

For a parking lot, both materials will require additional drainage systems for stormwater management, such as detention ponds and drainage grates. There are porous versions of both concrete and asphalt available, but they usually still require drainage when used in large areas like parking lots and are more than double the cost.

Climate Concerns – Blacktop vs Concrete Driveway

The amount of maintenance you’ll have to perform over the life of your driveway or parking lot will depend heavily on the local climate. Freeze-thaw cycles are detrimental to both concrete and asphalt.

The smallest amounts of water seeping into the surface of either material will eventually lead to cracks and other more serious damage if not dealt with. You’ll have to resurface your asphalt and reseal your concrete regularly if you want to avoid water damage.

Asphalt also absorbs heat and gets sticky in hot climates, while concrete easily cracks and degenerates under salt in cold climates. For this reason, climate should be a big consideration when considering an asphalt or concrete driveway.

Installation and Maintenance

Asphalt is much quicker to install than concrete, for a residential driveway it can be completed in about 2 days. For a parking lot, it can be done in under a week in most cases. Concrete can take up 6 days for a driveway, and much longer for a parking lot.

As far as maintenance is concerned, a well-maintained asphalt surface can last up to 20 years as long as it’s resurfaced every 3 years. Concrete can last anywhere from 30 to 60 years with proper maintenance. This includes resealing every 1-3 years.

Environmental Impact – Blacktop vs Concrete Driveway

Concrete and asphalt both release carbon into the air when produced. Asphalt is a bit more eco-friendly because it can be recycled, however concrete cannot usually be recycled. Asphalt does have an overall lower carbon footprint than concrete, though not a negligible one by any means.

Is There a Better Paving Option than Concrete or Asphalt?

Yes, there is a better paving option. Recent innovations in paving technology have led to the development of commercial-grade permeable plastic pavers, such as the PRO PLUS product from TRUEGRID. They outperform concrete and asphalt in just about every category.

When it comes to durability, TRUEGRID pavers are far more durable and long-lasting than concrete or asphalt. In terms of raw strength, they can handle the weight of a monster truck jumping off a ramp and landing on them without breaking. And, that’s before they’ve been filled with gravel.

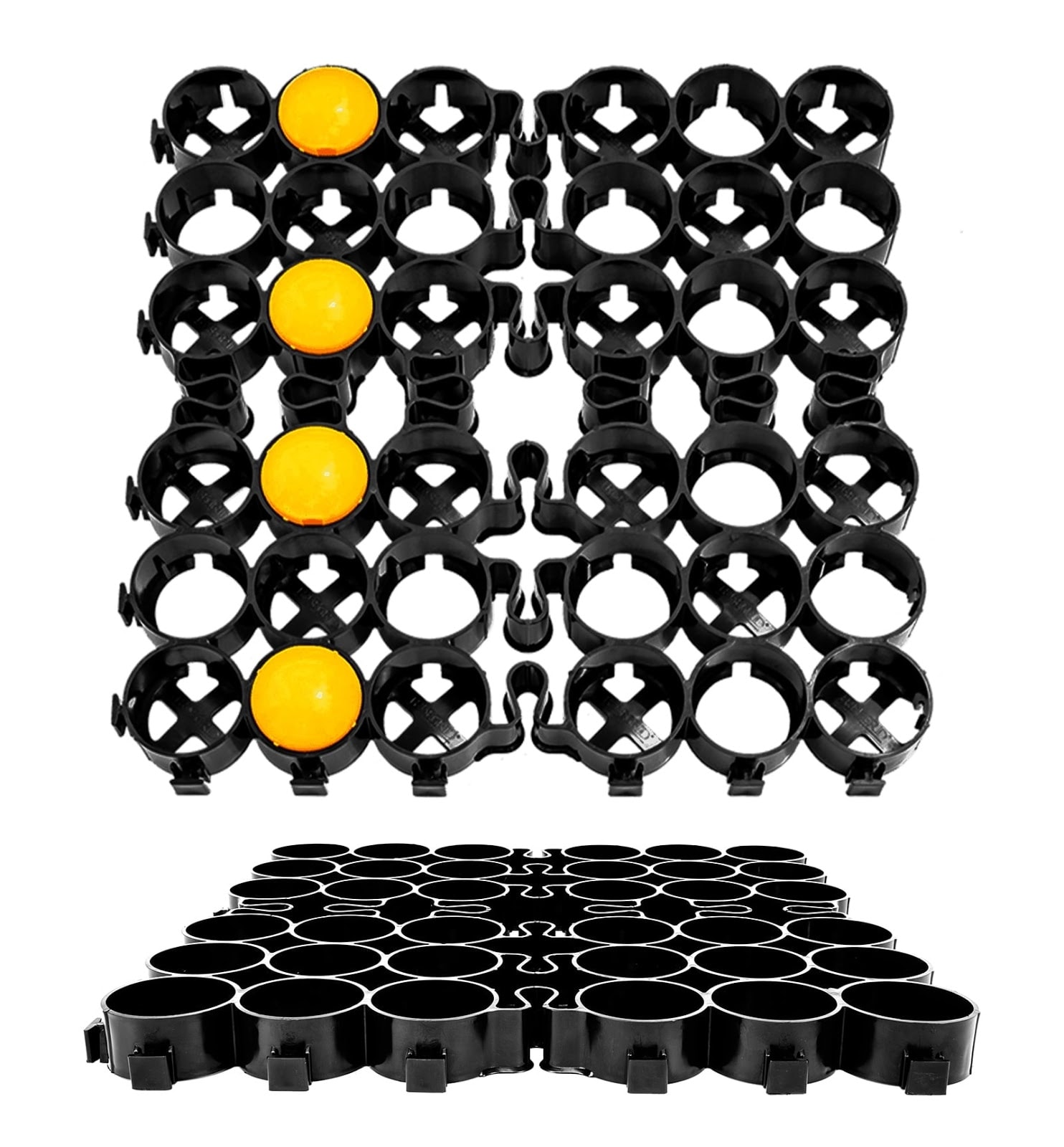

TRUEGRID permeable pavers are used to stabilize aggregates like gravel, turning them into a solid, level, unmoving paved surfaces. The installation process is as simple as excavating the desired paved area to a depth of about 12 inches. A filter fabric is laid at the bottom of the excavated area and a clean, angular aggregate is poured in and compacted. The base rock provides drainage and detention capacity as well as contributing to the strength of the system.

Next, the TRUEGRID pavers are snapped into place (as easily as Lego blocks) right over the top of the fill material. Then, more fill is poured into the top and compacted into the pavers with a heavy roller or vehicle. This completes the process, leaving you with a ready-to-use paved surface.

What Makes TRUEGRID Superior to Asphalt and Concrete?

TRUEGRID pavers have almost none of the downsides of concrete or asphalt. They require almost no maintenance, yet can last up to 60 years. They are unaffected by hot weather, cold weather, and everything in between.

They’re also 100% permeable, allowing stormwater to drain directly through them and eliminating the need for additional drainage. The installation process is much faster than asphalt or concrete, often able to be completed in a single day.

In terms of eco-friendliness, TRUEGRID plastic pavement stands head and shoulders above other pavement materials. It’s made from 100% post-consumer recycled plastic and has one of the lowest carbon footprints of any type of pavement. It also lessens the burden on local waterways, due to its permeability and elimination of stormwater runoff.

If you want a new driveway or parking lot that’s clean-cut, stylish, durable, low-maintenance, and eco-friendly, contact TRUEGRID today for a quote.

Everybody hates potholes. Potholes are a major nuisance for parking lots of all shapes and sizes. So, how to prevent potholes? Many business owners disregard parking lot damage like potholes as insignificant because they’re usually smaller in size and the speed of traffic going over them isn’t very fast. But, despite appearances, parking lot potholes can be dangerous when it comes to damaging vehicles and causing injuries.

In case you weren’t aware of just how detrimental potholes can be and what kind of damage they can cause, let’s take a closer look at them and how you can take steps to prevent potholes from ever occurring in your parking lot.

How are Parking Lot Potholes Dangerous?

Aside from being annoying to run over, parking lot potholes are dangerous in a variety of ways. The most obvious is the way they can damage the wheels and undercarriage of your vehicle when you run over them.

Potholes can have jagged edges, especially if they’re in an asphalt parking lot, which can cause a flat tire. If the pothole is deep enough, it can even cause damage to the wheel axle, suspension, and the wheel itself. This can lead to a claim for total wheel replacement, which is no small expense.

As a business owner, if you don’t know how to prevent potholes, you could be held liable for damage caused by them, for people as well as vehicles. For instance, if someone steps in a pothole and breaks their ankle or suffers another debilitating injury, it’s more than likely that you’ll be liable for their medical bills and more.

Another overlooked, a negative consequence of potholes is that they can cause drivers to reroute around them, leading to bottlenecks or worse, swerve to avoid them and cause an accident. This funnels all the weight and pressure of your parking lot traffic over smaller areas and leads to faster degradation of the lot, in addition to causing many more fender benders and small accidents.

Not repairing potholes is a big turnoff to consumers and could eventually hurt your bottom line once you develop a reputation for having a dangerous, broken-down parking lot.

Why Asphalt Develops Potholes

The reason why you see potholes develop much more frequently in asphalt is that it’s especially susceptible to water damage. Water gets in through cracks in the surface of the pavement, expanding and contracting to weaken the asphalt over time.

Eventually, combined with the pressure and weight of vehicle traffic, the weakened asphalt begins to crumble and break, leading to divots and ruts in the surface of the pavement. As these are continually driven over, the ruts and divots develop into full-blown potholes.

The Best Way to Prevent Potholes Forever

Asphalt and potholes go together like peanut butter and jelly, which is why you need an alternative paving material if you want to prevent them. The number one choice when it comes to durable, long-lasting, and stylish pavement to prevent potholes is permeable plastic pavers like the commercial-grade PRO PLUS system made by TRUEGRID.

TRUEGRID permeable pavers are the best choice for preventing potholes since they are made from 100% recycled plastic, and filled with small stones (gravel) that are locked into place on the surface. The pavers are easily snapped into place over a parking lot with a rock base of 8 to 12 inches in depth.

At the bottom, a filter fabric is laid to prevent the gravel from migrating, and the empty pit is filled in with gravel which is then compacted and leveled by a vehicle or heavy roller. Once the empty pavers are snapped together over the surface of the filled gravel pit, more gravel is poured over the top and pressed into the empty cells with a vehicle or heavy roller.

This process weighs the pavers down and prevents them from shifting or moving under the weight of traffic. Since these pavers are 100% permeable, they allow water and liquids to drain directly through them and into the soil below.

This not only eliminates the need for the drainage systems that commonly accompany asphalt, it makes the development of potholes impossible.

Pothole Prevention is Just One Benefit of TRUEGRID Permeable Pavers

The fact that potholes cannot develop in a TRUEGRID permeable paver lot is just a by-product of their innovative design. The extraordinarily durable plastic grids keep aggregate locked into place, providing a permanent level, solid surface for vehicles to turn, brake, and accelerate on without causing damage. Water has no negative effect on these pavers either, meaning they can last up to 50 years with only minimal maintenance.

They’re also one of the most eco-friendly industrial-strength paving solutions on the planet. Installation can be completed in as little as one day, and the overall cost of the pavers throughout their lifetime is much lower than that of asphalt or concrete.

Potholes are a dangerous nuisance that can cost you money and cause injuries and damage. If you want the best solution for how to prevent potholes in your parking lot for good, contact TRUEGRID today for a quote.

Many people think of gravel driveways as a low-cost, budget option, but the best gravels for driveways have evolved into something stylish. Now, there are multiple varieties of gravel driveways that are not only durable, but functional and decorative as well.

Some types of gravel driveways still have some vulnerabilities and potential downsides in the long-term, however there are others still that have seemingly managed to eliminate all of the usual pitfalls of using gravel for a driveway.

In case you’re interested in implementing a gravel driveway somewhere, let’s take a look at the best gravel for driveway usage and what the number one alternative to unstabilized gravel is.

How is a Conventional Gravel Driveway Built?

Most gravel driveways can be built with multiple different layers of gravel. The bottom layer of an unstabilized gravel driveway usually consists of clean stone, also known as base gravel. This gravel is typically laid at least 4 inches thick and is used to help with drainage. The stones are usually no larger than 2 inches in diameter.

Another option for the base layer of a gravel driveway is item #4. Item #4 is comprised of sand, dirt, and golf ball-sized stones. This type of gravel is available in a few different variations including recycled item # 4, which is made up of recycled stones, brick, blacktop, concrete, and rock.

There is also quarry item # 4, or crushed limestone, gray item # 4 which appears dark grey in color, and crushed bluestone item #4. Crushed bluestone item #4 is usually found in municipal driveways, though.

The middle layer of a gravel driveway features stones closer to golf ball size, with #57 stone being the prominent type of gravel. Otherwise known simply as crushed gravel, #57 stone also helps promote drainage.

Conventional Surface Gravels for Driveaway

There isn’t a lot of variety for the bottom layers of a gravel driveway, however, there are more options when it comes to finding the best gravel for driveway surfaces. Among the other options are crushed stone #411, quarry process, pea gravel, jersey shore gravel, marble chips, and river rock. These are the best options for driveway surfaces gravel, because they are small stones combined with rock dust, which makes a more solid driving surface.

1. Crushed Stone #411

It is crushed up #57 stone combined with rock dust. This mixture is able to handle moderate traffic from heavy vehicles.

2. Quarry Process

It is also called “crusher run” and works well for the surface of both driveways and walkways. It’s made from stone dust fines and crushed stone.

The stone dust will settle and become compact to create a semisolid surface that is smooth. It is important that you know that this type of surface gravel needs to be sloped towards the sides of your driveway for better drainage.

3. Pea Gravel

Pea gravel is popular gravel for driveway aesthetics. It’s made up of round, small stones that can come in many different colors. This type of gravel will easily migrate and spread under the weight of vehicles, though, and needs to be stabilized for long-term, maintenance-free usage. [Editors note: pea gravel is not recommended as a fill for permeable pavers]

4. Jersey Shore Gravel

It is made of yellow, tan, white, gold, and brownstones and looks quite a bit like sand. It’s similar to pea gravel since it needs borders or stabilizing pavers to prevent it from spreading.

5. Marble Chips

Marble chips are white and they sparkle in the sunlight. They typically cost more than other gravel types but are another favorite when it comes to being the best gravel for driveway aesthetic appeal. This type of gravel also needs a border or stabilization to prevent it from spreading, migrating, and washing away.

6. Blackstar or Blacktrap Rock

A very attractive dark gray gravel, this is an excellent choice as it is angular and locks together. When combined with stabilizing grid paving system, this provides a super durable and beautiful driveway.

A Better Alternative to a Typical Gravel Driveways

Some of the aforementioned gravel types require stabilization, but the best way to construct any gravel driveway is by using TRUEGRID permeable pavers to lock in your gravel.

TRUEGRID PRO LITE and PRO PLUS stabilizing pavers simply require excavation, geotextile fabric, a gravel base layer, the pavers (PRO PLUS or PRO LITE) and fill gravel.

After excavation, the base layer is placed on a piece of fabric of the excavated area where you want your driveway that provides drainage for water and other liquids. The base layer may be compacted in 2 to 4″ lifts and the area should be leveled.

TRUEGRID permeable pavers are snapped in place over the surface. Some cutting and repositioning of the pavers may be needed.

Next, your surface gravel/stone of choice is poured into the pavers level to the top. This weighs the pavers down and locks them securely into place. Suggested gravel infill is a hard, sharp/angular, uniform size — 1/2″, 5/8″ or 3/4″ for PRO PLUS — clean stone.

The main benefit of using TRUEGRID pavers to build a gravel driveway is that they will keep your gravel in place, eliminating the need for almost any maintenance during the course of your driveway’s lifetime.

A properly installed and maintained TRUEGRID gravel driveway is durable enough to handle all types of typical residential traffic and will last 25 years or more without cracking or breaking down in the sun, rain, or other types of weather like asphalt does. Choosing the best gravel for driveway usage is only part of the equation.

If you want to build your gravel driveway the maintenance-free way, get in touch with the pavement professionals at TRUEGRID today for a quote.

Commercial and industrial buildings need industrial pavement that can handle their needs. Too many builders, owners, architects, and designers gravitate towards inferior types of pavement when it comes to building their parking lots, roadways, sidewalks, and other areas around their buildings.

For lots that experience heavy traffic, large vehicles, and heavy equipment, asphalt and concrete are no longer the most effective paving solutions. Not only that, but they’re incredibly non-sustainable and have a huge carbon footprint. We’re seeing the negative consequences of our carbon emissions on a daily basis now, so the focus on sustainable materials has never been higher.

If you’re interested in implementing a superior industrial pavement alternative to asphalt or concrete, let’s take a look at one of the best solutions around and the many benefits it provides.

The Downsides of Concrete and Asphalt

For the longest time, asphalt and concrete have been the go-to materials for industrial pavement. However, even a residential asphalt driveway is subject to degradation and requires costly maintenance over its lifetime, so it goes without saying that concrete and asphalt are guaranteed to break down in industrial situations and will require expensive repairs in industrial situations.

For example, asphalt unravels and needs to be resurfaced once every 10 to 15 years, minimum, more in hot climates with truck traffic. It also cracks and potholes easily, and is vulnerable to water damage, especially in freeze-thaw climates. Concrete, while better in warm climates, is prone to cracking and water damage as well.

These materials also require expensive drainage systems and detention ponds, and they put a burden on local storm systems. They are also incredibly bad for the environment and release a lot of CO2 into the air when produced.

All of these factors add up to make them less than ideal for industrial pavement, especially in industrial and commercial settings where they see more traffic and stress.

The Best Paving Alternative for Commercial and Industrial Businesses

The number one paving solution for industrial and commercial purposes right now is permeable plastic pavement. TRUEGRID is a company that produces elite-quality pavers such as the TRUEGRID PRO PLUS paving system.

One of the main benefits of TRUEGRID pavers is their durability. They can last up to 60 years with only minimal maintenance required. They are weather-resistant, UV-resistant, and durable enough to handle daily 18 wheeler traffic.In one test demonstration of strength, a monster truck repeatedly drove off a ramp, went airborne and landed on TRUEGRID without any damage, and that’s before the pavers were filled with aggregate as they are in normal use. Aggregate fill stabilized with the grid pavers has a compression strength of over 8000 psi and is super tough and durable.

They’re also made from 100% recycled post-consumer plastic, making them one of the most eco-friendly products available. The TRUEGRID PRO PLUS system is 100% permeable, meaning it allows stormwater to drain directly through the pavers and into the filtering soil below.

This eliminates the need for costly drainage systems, which allows you to make 100% use of your land and reduce or eliminate a detention pond, and alleviates the burden on local storm systems as well by absorbing heavy rains and eliminating most runoff.

TRUEGRID Pavers are Quick to Install, Stylish, and Durable

The installation process for TRUEGRID PRO PLUS pavers is super quick and relatively large areas can be completed often and ready for use in a few days,, depending on the size of the lot and preparation requirements.. For an industrial lot that needs to support heavy vehicles hauling huge pieces of equipment and machinery, the installation is comparatively simple and quick.

First, the area to be paved is excavated to 10 to 12 inches and a filter fabric is laid at the bottom to keep separation of the soil and gravel layers. Next, gravel is poured into the pit, compacted, and leveled with a heavy roller. The TRUEGRID PRO PLUS pavers are then snapped into place (like Lego blocks) over the top of the gravel.

Afterward, more gravel is poured into the top of the pavers and compacted with a heavy roller or vehicle to complete the process. Once the empty cells on the surface are filled with gravel, it weighs the interlocking pavers to the ground and prevents them from shifting or moving.

Your paved area is then ready to handle frequent, heavy traffic without ever breaking down or requiring extensive maintenance. A TRUEGRID lot will last up to 60 years with little or no maintenance required.

You Don’t Need Dirty Materials for Durable Pavement

There’s a common misconception that concrete and asphalt are better suited for commercial and industrial pavement use, mostly because they’ve been around for so long.

Concrete and asphalt most often perform poorly compared to a product like TRUEGRID PRO PLUS pavers, and they’re also much worse for the environment. A TRUEGRID pavement solution means a lower overall cost for you, less burden on local waterways, and far less of a contribution to global warming.

If you want an industrial pavement solution for your business that looks professional and stylish, is durable enough to handle whatever type of traffic you throw at it, and works in far better harmony with nature, contact TRUEGRID today for a quote.