Permeable Commercial Paving as an Alternative to Asphalt and Concrete

[Posted on August 26th, 2015 by: Barry Stiles]

Asphalt and concrete are by far the two most common kinds of commercial paving used on company parking lots and access roads, but they do not come without their problems. Asphalt is popular because it is cheaper to install than concrete, but its maintenance needs are almost constant. Concrete is very expensive to lay down and needs fewer repairs than asphalt, but the repairs it does need tend to be quite costly.

Despite these and other limitations, businesses typically choose concrete or asphalt pavement because the only other option is gravel, which erodes, dusts up, sinks down, and gets muddy. The only advantage, in fact, that gravel seems to offer is that it is the cheapest option available. But what if there were a way to take advantage of the low cost of gravel while avoiding its shortcomings? In that case, it would become, in many situations, the very best choice for commercial pavement.

And here it is:

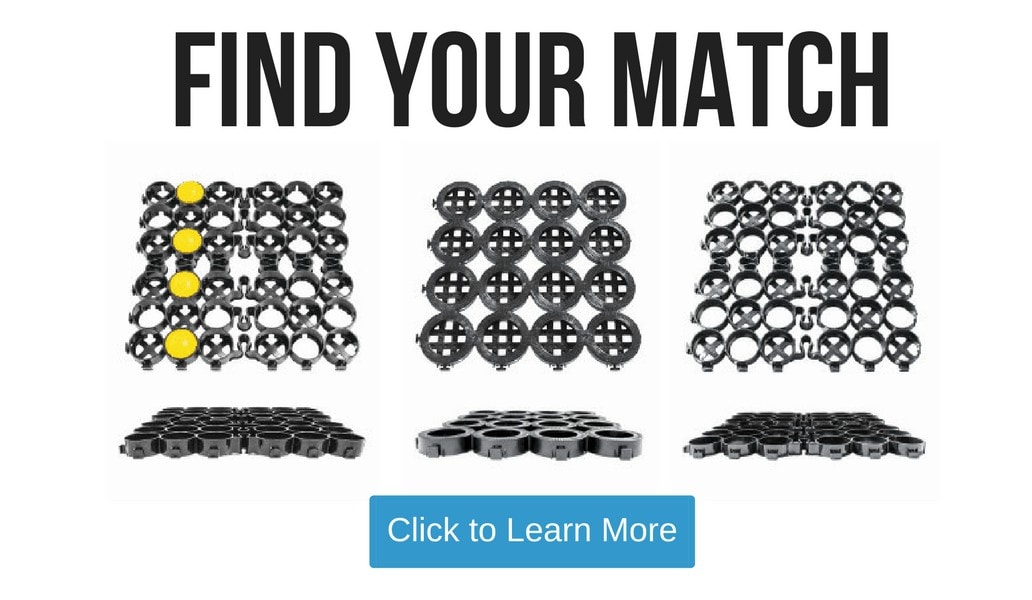

TRUEGRID pavers are a relatively new, innovative solution to many commercial paving problems. These durable plastic grids are installed above a drainage substrate and then filled in with an aggregate of your choice. Each rectangular piece is made up of numerous circular grid-sections, which are tied together by horseshoe-shaped connecting flex links for added strength. Rain and runoff water simply seep through the permeable pavement and disappear, while the grids hold the gravel in place and stand up against heavy pressure bearing down on them.

Some of the most important benefits of the TRUEGRID system are as follows:

- TRUEGRID pavers are cost-effective: The installation costs of this product is a third to a half that of asphalt or concrete, and it has virtually no maintenance costs. Because the plastic grids prevent gravel from wandering out of place or eroding away, there is less resurfacing to be done than with ordinary gravel driveways and parking lots.

- The pavement is 98% permeable: This high permeability prevents puddling, mud zones, and wash-outs. The substrate type and the fill depth can also be made more or less permeable, as needed, to meet local code requirements. Furthermore, land usage is greatly increased because the retention or detention structures are built right into the pavement’s sub-base.

- The load capacity is extremely great: TRUEGRID plastic reinforcements can bear 6,880 psi while still empty, and much more pressure once filled in with gravel. 85,000 + lb gravel trucks can drive on the grid with now problem prior to filling the grid with aggregate to speed the installation process. Weather will not significantly affect its ability to handle heavy loads. Its great strength makes it a first choice for semi-tractor parking lots, heavy equipment storage areas, and high-traffic access lanes.

- Vehicle wear and tear is reduced: Gravel-filled pavers produce much less strain on tires and axles while turning or maneuvering, and this will, over the course of time, translate into reduced vehicle maintenance needs.

- Gravel is kept firmly in place: Webbing often fails to keep gravel in its place, and concrete borders are expensive and still allow ruts to develop. TRUEGRID permeable pavers, however, prevent gravel spreading, stop rutting, and minimize dust-ups.

- It stays cool in the summer: Unlike asphalt and concrete, plastic-gridded gravel does not suffer from the “heat island effect.” You will not feel waves of heat rising off it nor feel it turn hot due to absorption of the summer heat.

- It does not deteriorate in the winter: The freeze/thaw cycle damages concrete and asphalt every winter, but gravel and grids are barely affected. Rock salt, which causes cracking in other pavements, will not damage a TRUEGRID system.

- TRUEGRID is the “greenest” commercial pavement: The pavers are made from 100% recycled plastic, and the sub-base drainage structure is formed from recycled concrete. Second, dirt can be used as a filler instead of gravel and grass grown on top of the pavement. Grassy parking areas often work well for overflow parking, fire lanes, golf cart paths, and more. They are certainly the most natural looking option. Finally, TRUEGRID pavers’ impact on the environment is low enough that it qualifies for LEED points, which can sometimes help sell properties to “green-conscious” land buyers.

- The TRUEGRID system puts safety first: These products are fully ADA compliant, and the grids make the gravel much less skid-prone than regular gravel because of the stability and friction they create.

- No re-striping will ever be needed: Parking space/lane markers lock into circular grid holes and can be moved fairly easily at a later date. You will not need to re-stripe, and you can re-arrange the space divisions as needed.

- The finished pavement is aesthetically pleasing: While beauty is in the eye of the beholder, most customers are enjoy the natural aesthetic of TRUEGRID pavements. Gravel fits well into a country setting, and the right colors of aggregate can complement nearby brick or stone structures in small towns. High-end retailers, even in the big cities, can do well by using gravel with attractive colors, textures, and sizes.

Using crushed gravel, or “self-binding gravel,” composed of a mix of larger particles and smaller ones (“fines”), helps to keep gravel from quickly deteriorating. A 20 to 60 year life cycle, equal or better than concrete and longer than asphalt is expected for a gravel filled TRUEGRID surface.

TRUEGRID is a Houston-based company that alone produces the commercial pavement system mentioned above. It offers nationwide shipping, and further information can be learned about its products by visiting their website and/or filling out an online information request form.

Sources:

www.angieslist.com/articles/pros-and-cons-asphalt-vs-concrete-driveway.htm

www.drivewayexpert.co.uk/advantages-disadvantages-gravel-driveways.html

www.landscaping.about.com/od/drivewaysandwalkways1/f/gravel_driveway.htm

[Posted on August 26th, 2015 by: Barry Stiles]

Up to the present time, roadways and parking lots have largely been developed with asphalt and concrete, using methods that are relatively harmful to the environment and ignore the principles of water conservation. In addition, the surfaces of these roadways and parking lots get baked by warm weather sunshine, and add to the general overheating of cities and towns.

While these commercial paving methods were accepted in the past as the best available construction practices, commercial paving now and in the future must take a more responsible approach to satisfying the requirements of commercial paving while also safeguarding our planet.

Here are 10 reasons why commercial paving methods now and in the future should have at their foundation green strategies which are mindful of long-term environmental impact.

#1 Low Impact Development (LID)

Low-impact development is a planning and engineering design approach whose chief aim is to accomplish a construction project with a view toward maintaining the environment to the greatest extent possible in its pre-construction state. Methods used will be those causing minimal impact to the environment, with the least disruption to both the local environment and local citizenry. In addition, strategies include those which prevent pollution from water runoff on paving surfaces, and instead allow for conservation of freshwater. Low impact development is the best approach to provide for enhanced natural resource protection.

#2 Cost effectiveness

Because permeable paving materials make use of recycled plastic, the cost of materials used is typically lower than other, traditional paving materials. Installation methods are also less costly because they don’t involve the use of as much heavy equipment or the large crews that are typically necessary for paving with asphalt or concrete. Using the green permeable paver approach, the total cost of a paving project can be as much as 50% less than the cost of comparable asphalt or concrete paving project. Even better, the end result is far friendlier to the environment.

#3 Recycling

The plastics used in permeable pavers are derived from recycled materials that would otherwise have taken up space in local landfills, and would eventually become an eyesore rather than a useful part of the local infrastructure. After recycling, these reclaimed plastics can support an incredible amount of weight, especially when configured as a grid.

#4 Pollution avoidance

When storms rain down on traditional paved roads and parking lots, the water runoff can easily become polluted with surface materials and find its way into the local groundwater. When a permeable paver system is installed, storm water has no harmful surface materials to hit and carry off into the water supply. Instead, rainwater seeps directly into the ground in the most natural manner possible, with no harmful surface substances.

#5 Water quality and collection

Instead of heavy rains causing erosion and possible floodwaters, water can easily seep through the upper levels of permeable pavers, typically composed of gravel or porous rock, into the sub-level and on into the groundwater. This collects water of a much better quality than surface runoff water, and allows water to easily enter the local groundwater system. Forward-thinking communities can even enhance this natural process by installing water collection systems during construction.

#6 Heat island effect

In the heat of summer, blazing sunshine strikes the surface of traditional paved roads and parking lots and reflects back up into the local atmosphere. During the daylight hours, this can create a significant cumulative effect, multiplying the impact of heat waves and creating a greenhouse atmosphere across the city landscape. This is not true of permeable paver systems, which do not reflect the warmth of the sun back up into the air. When the impacts of all roadways and all parking lots in a given city or town are added together, the heat gain can be enormous, creating an island of heat.

#7 Mud and dust control

In the midst of any dry spell in a town or city, the dust raised from normal traffic can be a cause for concern both for visibility and for breathing air. Conversely, during periods of very wet weather, water runoff from traditional road surfaces and grassy overflow parking lots can create mud holes which also cause problems. Neither of these two situations occurs with the use of permeable paver systems.

#8 Grass paving

Grass paving can be a very effective engineering approach, especially in the case of overflow parking lot areas. By using a plastic permeable paver base with grass fill, even the very heaviest weights can be supported, while the parking area remains aesthetically appealing. Since any heavy rain would seep directly into the ground and on into the groundwater system, the possibility of creating a mud pit in the parking area is avoided.

#9 Maintenance costs

Typical asphalt or concrete roadways and parking lots inevitably require maintenance and repairs, especially in areas where heavy snows occur, and road treatment and plowing services are required. In these communities, the Department of Transportation often maintains a summer crew of workers dedicated to such repairs, and local paving contractors are likewise kept busy. By contrast, maintenance costs for permeable pavers are virtually nil because they do not crack or degrade, and no potholes ever need filling.

#10 Adaptability

Because permeable paver solutions are modular in design and can easily be put together after analysis of specific local requirements, they can be adapted to almost any set of circumstances in any environment. Traditional methods are far less flexible, and often simply cannot provide an adequate solution for local requirements.

—

List of Sources:

http://www.greenparkingcouncil.org/featured/manifesto-future-parking-lots/

http://www.scgh.com/go-green/landscaping-and-outdoors/permeable-paving/