Permeable plastic pavers are redefining how driveways and walkways are built. These systems replace impermeable surfaces that contribute to flooding and erosion with grids that stabilize gravel or grass for a durable, eco-conscious surface. Their combination of strength, drainage, and sustainability makes them a trusted choice for homeowners, contractors, and municipalities.

Why Permeable Plastic Pavers Matter

Permeable paving grids address major site challenges such as drainage, stormwater control, and erosion prevention. Traditional asphalt or concrete sheds water, often overwhelming storm drains and creating pooling in streets or yards. Permeable plastic pavers go further by:

- Replenishing groundwater

- Limiting soil loss

- Filtering hydrocarbons and other roadway contaminants before runoff reaches waterways

Independent studies show permeable pavements can capture the vast majority of suspended solids and many pollutants, with additional treatment layers available if nutrient removal is required.

These systems also help:

- Moderate surface temperature

- Reducing heat absorption in summer

- Minimizing ice buildup in winter

Other permeable approaches, including gravel, grass, or specialized mixes like permeable concrete and asphalt, can provide some infiltration benefits. Yet these systems often lack the structural reliability or service life required for driveways and walkways. Permeable pavers unify infiltration with long-term stability, offering the most durable option across residential and municipal projects.

How Permeable Plastic Pavers Work

A base layer of crushed stone provides structural support and doubles as a detention zone for stormwater. This underground storage can reduce or right-size retention infrastructure, saving land that would otherwise be dedicated to ponds or basins. Above the stone, the plastic grid pavers interlock to form a continuous surface.

Once filled with gravel or turf, they create a pavement ready for vehicles or pedestrians. The system captures stormwater during peak flows and releases it gradually into the soil. This design prevents rutted gravel, standing water, and mud-tracked paths while helping projects meet stormwater regulations.

Driveways vs. Walkways

Driveways and walkways place very different demands on a paving system, so it’s important to consider how plastic grid pavers perform in each application.

Driveway Applications

Driveways are where plastic driveway pavers show their strength in practice. Vehicle loads quickly degrade loose gravel or soft asphalt. With permeable plastic pavers, weight spreads evenly through the grid and into the base, preventing ruts and potholes. They can support light residential cars or heavy trucks depending on grid type and base layer depth. A gravel-filled driveway built with plastic grid pavers stays functional for years, without constant patching or resealing.

Walkway Applications

Walkways demand less load capacity but often face puddling and surface shift. Plastic permeable pavers keep paths dry and steady, giving pedestrians a secure surface year-round. They can also be filled with grass for a softer, park-like appearance in gardens or community landscapes. The grid will protect the grass roots from compaction and provide a healthier plant.

Advantages Over Traditional Paving

Conventional paving systems can’t manage water or durability the way permeable grids do, which is why the differences matter for both safety and long-term cost.

Drainage and Stability

Asphalt and concrete trap water and usually require added drainage. Brick and stone allow some infiltration but shift over time, while loose gravel disperses and develops ruts. Permeable grids combine the best qualities: they drain like gravel, interlock like concrete, and remain stable under repeated use.

Seasonal Safety

Permeable grids also run cooler in summer and shed ice in winter by keeping water off the surface. That stability makes crossings safer and reduces reliance on storm sewers or costly retention ponds. By reducing ice buildup in winter and heat retention in summer, permeable surfaces also lower slip-and-fall risks and help keep pavement temperatures safer for both pedestrians and vehicles.

Long-Term Value

While upfront installation costs for permeable plastic pavers are often higher than gravel or asphalt, long-term savings come from reduced maintenance, fewer repairs, and extended service life. Many municipalities also offer stormwater fee credits or green infrastructure incentives, helping offset initial project costs.

Types of Plastic Pavers

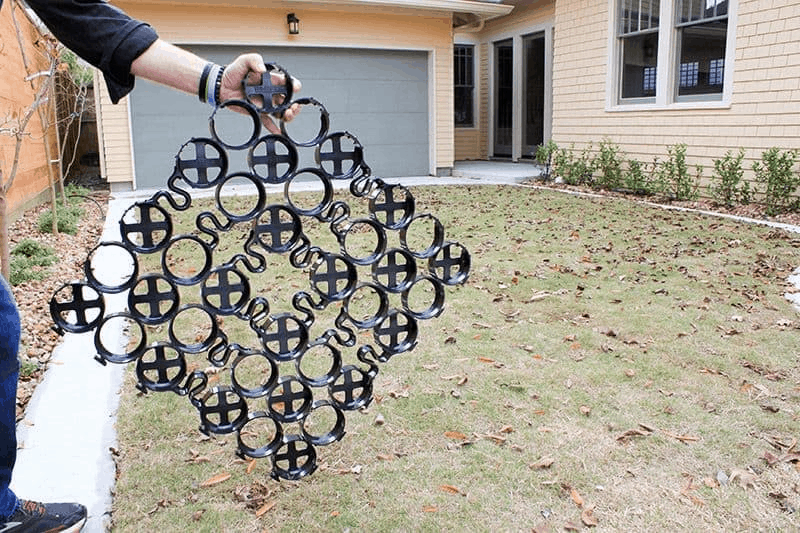

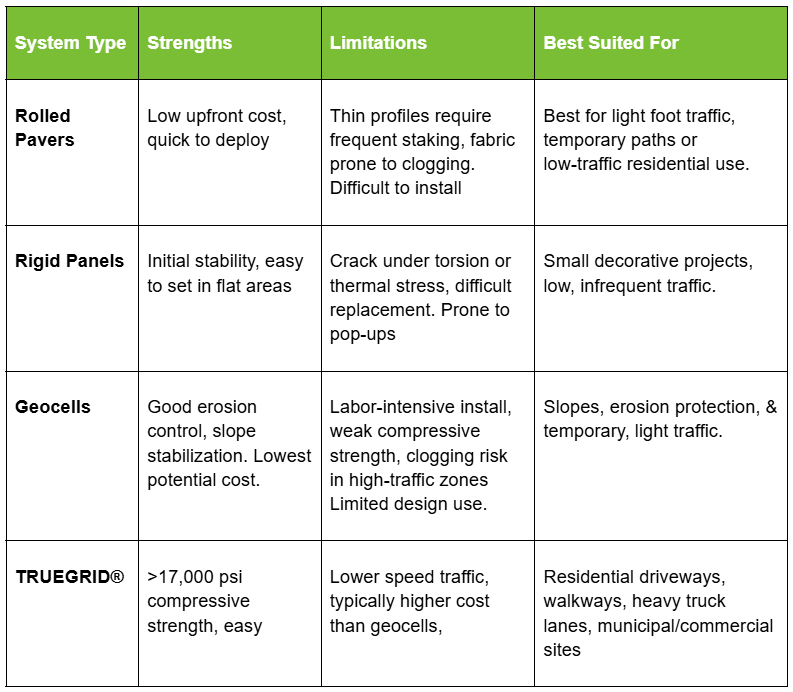

Not all plastic permeable pavers are equal, and knowing the weaknesses of common systems helps in selection.

- Rolled pavers are inexpensive and quick to deploy, but they often require staking every few feet to stay in place. Their thin profiles offer limited stiffness, alignment can be difficult during installation, and fabric backings are prone to clogging in fine soils.

- Rigid panel systems provide initial stability but may crack under torsional loads or during thermal cycling in hot and cold climates. Panel stiffness can also cause individual pavers to pop-up in corner or edges. Once a panel fails, replacement often means tearing up a large area.

- Geocells rely on aggregate confinement rather than panel strength, which can make installation labor-intensive. Performance depends on geometry, infill, and construction quality, and maintenance may be needed in high-traffic or high-fines environments. Complex site designs are difficult to achieve with geocells.

- TRUEGRID pavers address these issues by combining high compressive strength with wide cells that resist clogging and torsion and flexibility to move with soil & dynamic loading changes. They distribute loads effectively, handle heavy traffic, and last decades without major failures.

Plastic Paver System Comparison

TRUEGRID System Strengths

TRUEGRID pavers combine durability, sustainability, and design flexibility in ways that set them apart from other permeable systems.

Sustainable Construction

Made from 100% recycled plastic, TRUEGRID panels divert waste from landfills, or from ending up in the ocean, while offering exceptional compressive strength.

Efficient Installation

Interlocking panels snap together and cut cleanly for curves or edges, allowing crews to cover large areas quickly.

Flexible Design Options

The open-cell structure supports either gravel or grass fill, with options for different stone colors or turf varieties to match site aesthetics. This flexibility allows designers to match paver surfaces to architectural themes or landscape palettes, whether it’s a natural grass courtyard, a crisp white stone driveway, or a mixed-use path that blends hardscape with green space.

Proven Durability

Built to resist UV exposure, freeze-thaw cycles, and heavy loading, TRUEGRID pavers maintain strength for decades with little upkeep. Laboratory tests confirm compressive strength exceeding 17,000 psi, which translates to reliable performance under anything from residential driveways to heavy truck lanes. By specifying grid depth and base thickness, engineers can tailor load ratings for light vehicles, fire access, or industrial yards.

Installation Process

Installation is straightforward but demands proper preparation:

- Contractors excavate to the required depth

- Install a geotextile to separate soil and stone

- Place a graded, or drainage rock, base layer

After compaction, the grids are laid, locked, and filled with gravel or turf.

For driveways, deeper bases absorb higher loads; for walkways, excavation may be shallower. The result is a stable permeable surface installed more efficiently than concrete or brick. TRUEGRID provides detailed guidance, including an eight-step installation method that covers excavation, grading, and fill.

Maintenance and Long-Term Performance

Gravel-filled permeable paving grids remain firm, rarely even needing top-dressing. Grass-filled systems require mowing and irrigation, nothing beyond standard lawn care. By controlling water at the surface, puddling, frost heave, and cracking are minimized. Sites often need less de-icing salt in winter because the surface drains rather than holding water. Over time, owners avoid expensive asphalt patching or concrete replacement.

Applications for Homeowners and Municipalities

Permeable plastic pavers adapt to a wide range of projects, from residential driveways to large-scale municipal infrastructure.

Homeowner Applications

For homeowners, plastic pavers for driveway projects combine function and curb appeal. A suburban two-car driveway filled with clean gravel provides a finished look without flooding concerns. In a backyard garden, grass-filled pavers create natural-looking walkways that stay firm through rain and foot traffic. These simple, low-maintenance options help homeowners protect their property while adding value.

Municipal and Commercial Applications

For municipalities and commercial properties, permeable grids support compliance with stormwater rules while lowering maintenance needs. They help meet environmental codes for water treatment and runoff reduction. TRUEGRID systems handle heavy traffic, integrate with landscaping, and support goals such as LEED certification. Businesses and communities also benefit from the visual appeal of green or gravel-filled designs, which can improve public perception while meeting functional needs and reducing the Urban Heat Island effect.

Choosing the Right System

Project demands guide the system choice. Plastic permeable pavers for walkways should balance comfort, stability, and appearance. Driveways need higher load-bearing capacity. TRUEGRID offers products that scale from light residential use to heavy commercial traffic. Contractors and designers can compare compressive strength, cell depth, and fill to find the right match. Whether filled with gravel for strength or grass for a green surface, the system adapts to the site.

A Sustainable Shift

The move toward permeable plastic pavers reflects a broader trend in sustainable design. As cities and homeowners reduce flooding, meet stormwater mandates, and pursue greener landscapes, these systems provide a practical and cost-effective path. They unite stormwater control, durability, and flexibility in a way conventional paving cannot.

Build with TRUEGRID Permeable Pavers for Lasting Performance

TRUEGRID manufactures permeable plastic paver systems designed to handle real-world loads while protecting the environment. Our products simplify installation, reduce maintenance, and outperform traditional paving for decades. Contact us today for more information.

[…] pavers can be durable but lack style and are not very eco-friendly either. Gravel or grass filled plastic pavers are the most durable type available and have a variety of styles to choose from. They are the most […]

[…] and more aggregate, either different or the same type, is poured into the cells the pavers. The plastic pavers hold the fill gravel in place so there is no maintenance for this stabilized patio surface. The […]

[…] they are made from plastic and can be filled with grass or gravel, they require almost zero maintenance and can last as long […]

[…] to pave a commercial or residential area, there are better alternatives to clay brick pavers. Permeable plastic pavers, for instance, provide you with a clean, attractive surface that is far more durable and […]

[…] expected to be in high demand is the PRO PLUS® permeable pavement system from TRUEGRID. Their permeable plastic pavers are made from 100% recycled plastic and are tough enough to handle the weight of a falling monster […]

[…] with the results. TRUEGRID was able to save them $12,000 on the fueling station alone by using permeable plastic pavers instead of concrete. Now they have a fueling station that will never rut, hold standing water, or […]

[…] permanent solution to stabilizing a muddy road is to install permeable pavement. For example, the plastic permeable pavers made by TRUEGRID are able to hold gravel securely in place while providing a dry and level surface […]