Which is the Best Choice for Your Paving Project

Developers, architects and civil engineers face a critical task.

They need to provide enough parking and surface storage for their projects, but in an environmentally conscious way.

This requires…

-

Urban flooding after heavy rain. Using paving surfaces that rainwater can infiltrate instead of running off

- Using environmentally friendly materials

Traditional paving surfaces such as asphalt and concrete do not allow rainwater to infiltrate into the soil. The result? Urban flooding has become an increasing problem.

Retention ponds can be used to control runoff but take up large areas. For example, a 120,000 square foot parking area could require that 21 percent of the space be reserved for a retention pond. This is a loss of 25,000 square feet of useful space.

Asphalt can also leach toxic chemicals into the water table. Even with the use of retention ponds this can create serious environmental issues.

Two Eco-Friendly Paving Solutions

Two different paving systems can mitigate surface runoff and also use eco-friendly materials and techniques.

Pervious concrete. Also called “permeable pavement” this method uses only coarse aggregate and cement, but with no sand in the mix. This increases both porosity (void space) and permeability (the ability to conduct water). Both aggregate and cement are environmentally inert materials.

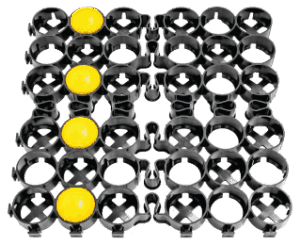

Permeable paver grid systems. This second option uses an open, plastic grid made from an inert material such as high-density polyethylene (HDPE). The grid is then filled with a washed angular aggregate. An example of this, TRUEGRID®, is considered the premier permeable grid paver system currently available.

But which is the best choice? Both systems use eco-friendly materials. Both allow rainwater to infiltrate the soil. Let’s compare these two paving solutions.

- Cost

Construction costs can vary, but permeable paver systems typically are 33%-50% below the price of standard concrete construction. Permeable concrete is more expensive than standard concrete, making Permeable Pavers even more economical.

- Ease of Installation

Concrete, whether standard or pervious, needs several days to “cure” once poured. During this time, it must be closely monitored and protected. The process has to be repeated for each individual section poured. You can’t walk or drive on the surface until it has completely cured.

Permeable paver installation is fast. For example, one person can install 1,000 square feet of grid of TRUEGRID pavers per day.

Once the grid is in place…even before the aggregate is installed…you can walk and drive on it. This avoids construction delays.

- Strength

Pervious concrete has an average compressive strength of 2500 psi with a range of 500-4000 psi. Actual strength depends on the specific mix of cement and aggregate…and requires lab testing to confirm.

The compressive strength of aggregate-filled permeable paver systems can exceed pervious concrete. For example, TRUEGRID pavers compressive strength ranges from 6500 psi (residential) to 8000 psi (commercial).

- Ongoing maintenance

Once the pavement or pavers are installed, we need to look at the cost of keeping the surface attractive and usable.

Pervious concrete pavement is not completely maintenance free:

Painted markings require periodic re-painting

These cracks must be repaired to prevent additional damage. Cracks can form due to shifting soil, temperature variations and precipitation.

TRUEGRID systems, however, are virtually maintenance-free:

The HDPE grid flexes using patented S-joints to adapt to shifting substrate. This prevents cracking.

Durable, maintenance-free SuperSpot® markers are inserted into the grid to provide surface markings. SuperSpot color is throughout the material, so the color cannot wear off.

- Infiltration capacity

Water infiltration rates for pervious concrete range from 288-770 inches per hour. For TRUEGRID systems, infiltration typically exceeds 800 inches per hour.

Not only does TRUEGRID exceed the infiltration capacity of pervious concrete, it also exceeds the highest rainfall intensities recorded in most areas of the United States.

- Eco-friendliness

Besides using environmentally inert aggregate for fill, TRUEGRID is manufactured from 100% post-consumer recycled HDPE. This creates an environmentally safe paving surface plus reduces landfill use.

The final analysis

Both TRUEGRID and pervious concrete provide eco-friendly solutions to the surface water issue.

However, TRUEGRID offers several advantages over pervious concrete, including the following:

- Lower cost

- Easier installation

- Greater strength

- Less maintenance

- Higher water infiltration

- Better use of recycled materials

Local and state governments will continue to press for sustainable solutions to combat local flooding and groundwater issues. TRUEGRID provides developers and property owners with an effective, eco-friendly tool to mitigate surface runoff.

For more information on TRUEGRID permeable pavers or to request a quote, visit www.truegridpaver.com