Creating an area in your business that can handle everything from a toddler’s walk to a large commercial vehicle is a daunting task. Most engineers and architects immediately turn to traditional materials, such as concrete and asphalt. But the same old paving methods are many. These materials may require regular maintenance, cause flooding, pollutant runoff, pothole or crack in extreme weather and are not the most environmentally friendly or aesthetically appealing.

Plastic pavers are rapidly becoming the new paving solution architects, builders, engineers, and even homeowners are turning to. The significant benefits versus traditional concrete pavers, gravel, or asphalt. Businesses and outdoor spaces can take advantage of this technology to completely transform their businesses. Plastic pavers are filled with grass or gravel and create walkable, driveable surfaces that drain quickly and look good. Businesses can benefit from durable, driveable surfaces for their use or for their customers, while garnering support from their communities by creating innovative green spaces.

Why Use Plastic Pavers

Many designers are unaware that new plastic paver systems can be a direct replacement for traditional hardscape and yield a number of benefits over concrete or asphalt. 100% permeability so water is absorbed instantly; stormwater detention under the surface to save land; pollutant filtering of runoff toxins; reduced heat island effect in urban areas creating a cooler site; more green space and a natural aesthetic when the pavers are filled with gravel or grass.

Stormwater runoff is the primary reason that architects and engineers install plastic pavers. Preventing flooding, increasing stormwater detention on a site is critical in the age of extreme weather events. Some plastic paver systems absorb rain at over 1000 inches per hour, preventing flooding, ponding or pooling and reducing the runoff to zero. When used with a clean washed rock base under the pavers stormwater can be retained, stored and released slowly to protect homes and businesses from rising waters. This is a contrast to impervious hardscape surfaces such as asphalt or concrete which cause water to rise, overwhelm city drainage systems and cause billions of dollars of damage and trauma to flood-ravaged communities. Permeable plastic pavers are part of the solution.

Removing pollutants from the stormwater before it recharges aquifers is a huge benefit of plastic systems. By allowing infiltration into the soil, as opposed to runoff of concrete, auto and other pollutants such as hydrogen, nitrogen, phosphorous, and various hydrocarbons are naturally filtered via the bioremediation process. Permeable plastic pavers allowing infiltration and natural filtering can remove up to 90% of pollutants from the water table.

Less drastic temperatures is another benefit of using plastic pavers. In the winter, there will be less ice buildup as any precipitation will seep through the paver. In the summer, there will be no extreme heat on the surface as the fill material will be cooler than concrete or asphalt. This will lead to a safer environment for all.

Aesthetically, plastic pavers allow for many options with different fill materials. Any color gravel or grass. Plastic pavers can be filled with gravel for highly trafficked commercial and industrial parking lots yielding a maintenance-free stabilized parking and driving area. They also can be filled with grass for fire lanes, driveways and light trafficked areas to provide green space and stabilized, strengthened, reinforced grass pavement.

Types of Plastic Pavers

Choosing a plastic paver will have dramatic consequences on the area you are installing it on. There are four different types of plastic pavers that are currently available on the market. They all have different qualities. Engineers and architects should carefully evaluate each type to find the type that will work the best for their case.

Rolled Pavers (also called “Roll Pavers”)

These plastic pavers come in, you guessed it, a large roll. The roll size is typically four feet wide and up to 150 feet long and the pavers are completely flexible.

Rigid Plastic Pavers

These pavers (sometimes also called “Panel Pavers”) come in both connecting and non-connecting varieties. Typically the designs use a honeycomb pattern arranged into a long and large grids rectangular shape. Sections have to be cut off during installation as the standard grid sizes do not fit most applications.

Geocell

These are strips of thin plastic that are connected to form an expandable mesh. Geocells are also known as cellular confinement systems and utilize ultrasonically welded high-density polyethylene (HDPE) strips or novel polymeric alloy (NPA) for their structures.

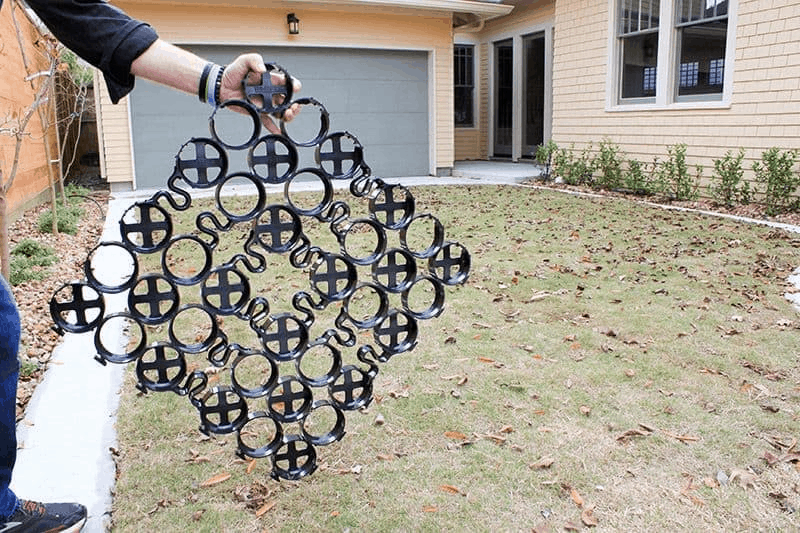

TRUEGRID

Inspired by LEGO bricks, TRUEGRID plastic pavers are square sections of permeable pavers that click together to cover any shape of area such as a parking lot or driveway. These are made of thicker HDPE which balances rigidity and flexibility.

Pros and Cons of Different Plastic Paver Systems

Rolled Pavers Pros and Cons

Pros of Rolled Pavers

– Typically made from 100% recycled plastic

Cons of Rolled Pavers

– Installation – Rolling out these pavers may seem easy but aligning the rolls and connecting them is most decidedly not easy. Rolled pavers require staking every 3 feet to prevent the flexible rolls from moving and coming up. Another disadvantage in commercial applications is that the rolled pavers are not strong enough to support gravel trucks driving and dumping loads on them during installation. This makes the fill process much longer and labor intensive. Having to move, reposition, and connect large rolls (96 to 600 sq ft each) can be a challenge. The edges of the long, heavy rolls must be aligned perfectly so that the plastic connectors on the edge of one roll can connect the other roll. Once a roll is placed on the ground, it is difficult to move due to the size and weight of the roll. The large size of each roll can also be a disadvantage when fitting the pavers to the paved area.

-Lower Strength: The cell walls in rolled pavers are thinner than other plastic paving systems, therefore the product can buckle under pressure. Rolled pavers do not have any flex joints. When vehicles turn they can easily twist the grid enough where it completely disconnects.

-Stake Installation Required: An installation challenge with rolled pavers is that they have to be staked every 3 feet. That means you and your team are going to spend extra hours and dollars installing this type of plastic paver. The installation process is already rather difficult and adding the extra steps can turn a potential buyer off from the system.

-Clogging: Some rolled plastic pavers have a fabric attached to the bottom of the paver to add strength and stability. This fabric tends to clog very quickly and suddenly the “permeable paver” becomes impermeable.

Rigid Pavers (Non-Connecting Pavers) Pros and Cons

Pros of Rigid Pavers

-Suitable for light-duty grass applications: Rigid plastic pavers have been shown to work for grass-filled applications. Purely foot traffic areas may be the best choice for these type of plastic pavers. There will not be too much force to break any of the connectors that hold the entire structure together.

Cons of Rigid Pavers

-Low Flexibility: Rigid plastic pavers are, unsurprisingly, inflexible. That is an issue if there is any ground variation or slope in the area where you are trying to install the plastic pavers. Low flexibility means these pavers may not hug the ground and portions of the pavers could then crack due to insufficient support underneath.

– Lower torsional strength. These pavers have a low ability to withstand the forces of a twisting load. This problem appears when trucks or cars make turns on these pavers. The torque force of vehicles turning can break the connectors off the edges of these pavers. This can result in the edges of these pavers popping up and then getting pulled or snagged by vehicles, resulting in more damage to the pavers, vehicles, or both.

-Susceptible to Cracking: When the temperature rises and falls throughout the year there is a high chance that the paver will end up cracking. Due to the coefficient of thermal expansion of the material and the stiffness of the overall structure this paver may experience due to temperature and weather changes.

Geocell Pavers Pros and Cons

Pros of Geocell Pavers

– Inexpensive. Because of their lightweight construction (using thin plastic) and collapsible design, Geocell pavers are less expensive than other pavers.

– Suitable for foot traffic or light-duty applications without vehicles where there is little chance of the fill gravel being disturbed.

Cons of Geocell Pavers

-No Compressive or Tensile Strength: One of the biggest issues of geocell plastic pavers is that they have almost zero compressive and tensile strength. The lack of compressive strength means that the gravel fill is bearing nearly all of the load. When the gravel in the geocell pavers is disturbed, the exposed edges of the geocell pavers get crumpled under the weight of vehicles. This leads to durability problems for geocell pavers. The pavers eventually break down and cannot withstand large loads.

-Challenging Installation: Since geocell plastic pavers are made from an expandable mesh, installation requires stakes, clips, anchors, and stake drivers. This increases the overall cost of the plastic paver system and the installation time.

-Long Term Problems: A recurring issue with geocells is their lack of durability. The required lifetime for some surfaces is 20 to 25 years and geocells simply do not last anywhere near that long. Geocell lifetime is measured in months, not years.

TRUEGRID Pavers Pros and Cons

Pros of TRUEGRID Pavers

– Strength: With a compressive strength of over 8,000 psi, there are few pavers that can stand up to TRUEGRID. For reference concrete typically has a compressive strength of 5000 psi for commercial applications. Even the empty grid can easily handle 40-ton gravel trucks during the installation process to speed rock fill.

– Durability. TRUEGRID plastic pavers have a lifetime of 25 to 60 years depending on the application, which is longer than asphalt and as long as concrete. This is one of the main reasons TRUEGRID dominates the commercial and industrial markets for plastic pavers. TRUEGRID was the first and is still the only plastic paver that has been successful in millions of square feet of commercial parking lots and truckyards across the world. That completely overshadows some of the other plastic pavers that are currently on the market.

-Easy Installation: After the surface is prepared, the TRUEGRID pavers can easily be installed with just a small crew. The grid size is also very small compared to other types of plastic pavers. This allows for fewer cuts needed when installing the plastic paver.

-Slopes and Inclines: TRUEGRID has the best of both worlds, strength and flexibility. The grid pavers can be installed on a slope up to 20 degrees without staking and is very accepting of uneven terrain and elevation changes..

Cons of TRUEGRID Pavers

TRUEGRID plastic pavement system, while typically less expensive than concrete, is more expensive than asphalt unless added drainage elements and a detention pond is required.

ADA Compliance

You can have plastic pavers and have an ADA compliant surface. Be sure to choose the right fill and minimize transition heights to be ADA compliant. See manufacturer for guidance.

Checklist for considering plastic pavers

Traffic loads. Is the plastic paver designed for heavy traffic or loads?

☐ Staking. Is staking required?

☐ Maintenance. Will maintenance be minimal?

☐ Stormwater detention. What stormwater detention is needed, and how much detention do the pavers provide?

☐ Strength. What is the compressive strength of the pavers? What is the torsional strength?

☐ Flexibility. Does the paver have flexibility to move with loads and ground movement?