WHERE CAN I FIND PERVIOUS PAVEMENT MANUFACTURERS?

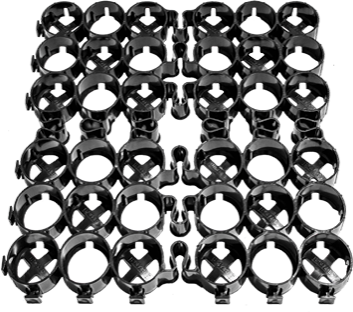

The world’s strongest permeable pavers, can be found at www.TRUEGRIDpavers.com. Our pervious pavers are proudly made in the USA and are shipped factory direct! Manufactured from 100% post-consumer recycled plastic, our high-quality pavers are shipped nationwide directly from the factory, providing significant savings by eliminating distributors and middlemen. We have stock on hand that can be shipped within 24 hours for smaller orders, while our high speed manufacturing processes allow us to fulfill large orders which may have custom specifications involved. Click on the Projects tab above to see some of the awesome uses for our pervious pavers.

WHAT DO PERVIOUS PAVERS TYPICALLY COST?

Compared to a concrete installation, an installation using the TRUEGRID permeable paving system typically runs 20-50% less and is competitive with asphalt. In jobs with additional drainage elements required for with asphalt and concrete installations, the savings with pervious pavers are maximized. TRUEGRID sites eliminate the need for retention/detention ponds which not only are expensive to build, but require a significant amount of land. The full cost depends on the size of the order, site preparation and the costs associated with the fill material, typically rock, gravel or grass that can be sourced locally. TRUEGRID installations require significantly less site preparation as well as much lower labor costs. The simple installation process makes it possible for not only professional paving contractors or landscapers to set up, but also do-it-yourselfers with little or no training. The easy to assemble system goes together quickly and easily. Often the largest savings beyond the square foot cost, and one that is often key for commercial and industrial projects,is that land utilization is 100% with the use of our TRUEGRID system. With the proper sub-base, TRUEGRID eliminates the necessity for detention or retention ponds which are often required of conventional pavements. The sub-base and paver void space in your TRUEGRID installation acts as a retention or detention area, saving the loss of profit from unused land, vital when the cost of land tends to be the highest expense in a project. Because our TRUEGRID pervious pavers eliminate the necessity for concrete retention or detention ponds, it saves these often expensive portions of the project, helping you come in under budget and remain environmentally friendly. To take a look at our specs and technical drawings available for our TRUEGRID paver system, please click on the Engineers & Architects tab at the top of the page.

WHAT IS THE DIFFERENCE BETWEEN A POROUS CONCRETE SYSTEM AND A PERVIOUS INTERLOCKING SYSTEM?

Lightweight, easy to handle TRUEGRID permeable interlocking pavers install quickly at over 1000 square feet per man-hour without tools, minimizing your labor costs. TRUEGRID pavers provide 98% permeability prior to filling, maintaining high flow rates when filled with gravel or grass. Compared to a similar concrete installation, the cost of TRUEGRID pavers, the sub-base material and your chosen fill material is significantly lower. By comparison, concrete porous pavers have lower drainage rates, require frequent cleaning and maintenance, are heavy and difficult to work with and typically cost 20% more than impervious concrete, or 50% more than the TRUEGRID system. For more information, please call our experts at the above number!

Testimonials

Low Impact Development (LID) is important to us. Our engineers and the city agreed TRUEGRID was the way to go.

Super easy to install! Love the results! I will send photos!