Gravel parking lots aren’t the most common type of parking lot you’ll find adjacent to most businesses, but they are practical in some scenarios. Gravel parking lots are typically cheaper than asphalt or concrete parking lots, making them a popular choice for smaller businesses or temporary parking solutions.

One of the biggest drawbacks of using gravel to build a parking lot, however, is the fact that they are incredibly prone to failing and need constant maintenance if built as a gravel-only lot without a stabilizing system to keep the gravel in place.

Other drawbacks are the mud, ruts, or dust that are come with weather and traffic.

In case you’re a business owner or someone tasked with maintaining a parking lot made of gravel, let’s go over the single most effective way to eliminate the chance of catastrophic gravel parking lot failure and constant maintenance.

Setting Up Your Commercial Gravel Parking Lot for Success

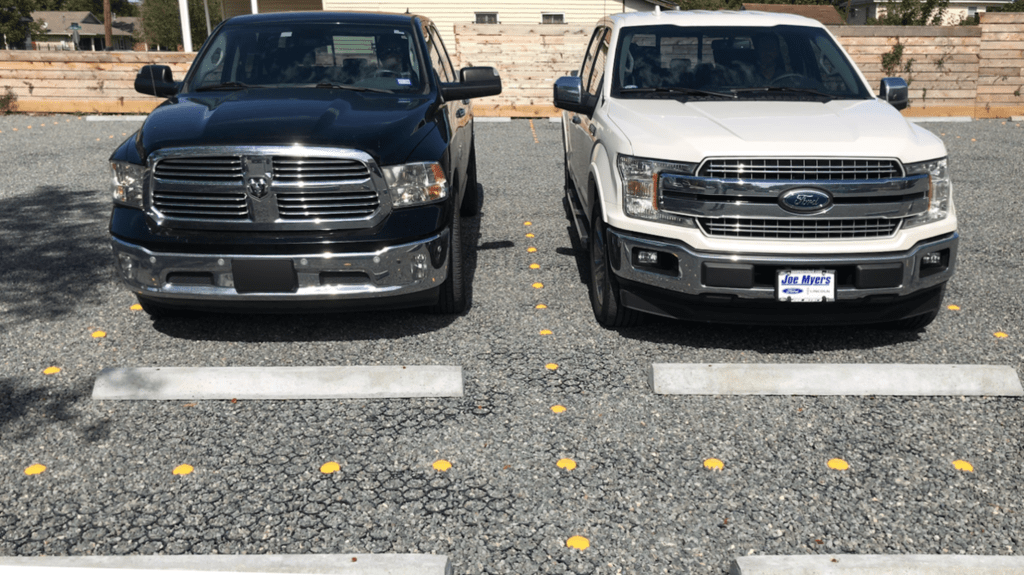

Commercial parking lots have a heavier burden to bear than parking lots for smaller, more residential-type businesses on average. The amount of traffic and abuse they need to be able to withstand is much greater, which is why any commercial gravel parking lot is guaranteed to fail without the right gravel stabilization.

Gravel alone is loose by nature, and not held together with any type of adhesive the way concrete and asphalt parking lots are. A commercial gravel parking lot without gravel pavers can function well for a little while, but will eventually begin to spread and disperse and the gravel migrates under constant pressure from turning wheels and walking feet. In wet weather that means mud, ruts, and puddles. In dry climates that means compacted gravel and dust.

You might think that makes gravel a totally impractical material for use in a commercial parking lot, but that isn’t the case. With gravel pavers like the ones produced by TRUEGRID, any commercial business can easily maintain a functional, high-performing gravel parking lot for many years without a problem.

How to Stabilize Your Gravel Parking Lot with Grid Gravel Stabilizers

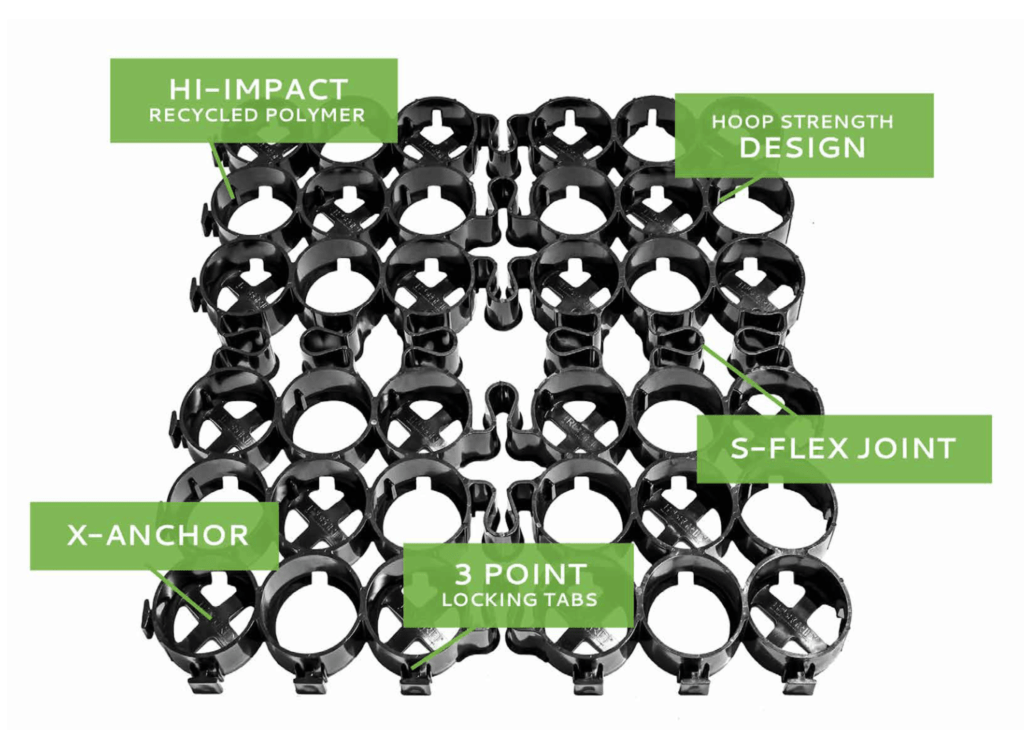

The only way to ensure a commercial gravel parking lot lasts as long as concrete is to stabilize it with a grid. The pavers from TRUEGRID are the best example of this type of grid. This patented interlocking gravel stabilization grid is comprised of super strong 1.8” deep cylinders groupings linked together by unique flex joints. When filled with gravel, the grid system has greater compressive strength than concrete and sufficient flexibility to never crack like asphalt or concrete. The grid cells keep the gravel in-place so maintenance or refilling of gravel.

There are other methods for gravel stabilization such as borders and webbing, but they don’t work well in commercial use when it comes to preventing the wear and tear of gravel due to traffic which leads to dust and ruts.

TRUEGRID pavers are the only product that prevents all of these problems. Due to its unique design, it eliminates the need for gravel refills and the frequent maintenance required with other stabilizing methods.

Unique Benefits of TRUEGRID Pavers

The patented 100 % permeable design of TRUEGRID gravel stabilizer allows for the effortless prevention of flooding, runoff, and erosion so commonly found in other gravel parking lots. The permeable nature of the gravel stabilizing pavers allows rainwater and runoff to drain directly through the grid and into the soil beneath where it can naturally be filtered, detained and released slowly in natural aquifers recharge.

Another major benefit of using a gravel stabilizer grid system from TRUEGRID is the elimination of the “heat island” effect we see so often in other parking lots. This is caused by hardscape parking lots that absorb the sun’s heat and don’t allow surrounding air to freely circulate, which leads to uncomfortably hot situations for customers and employees during the hotter parts of the year.

The gravel-filled permeable pavers have 40 % void or air space which eliminates this effect and does not allow heat to sit and accumulate directly over your parking lot.

Who Benefits Most from Gravel Stabilization Grids?

If you’re a business owner considering implementing a gravel stabilizer grid for your parking lot, there are some additional benefits to having a permeable gravel lot.

If you get heavy traffic in your gravel parking lot, want to prevent flooding, erosion, and heat islands, or you want to spend virtually nothing on parking lot maintenance for decades to come, then permeable pavers from TRUEGRID might be for you.

If you have crops, livestock, or nearby residents that might suffer from the dangerous clouds of dust from unstabilized gravel lots, a gravel stabilization grid is perfect for you. Preventing the pulverization and compaction of gravel with this commercial-grade grid system eliminates dust and allows natural water flow and infiltration at over 1000 inches per hour. All these help protect your local environment and can save money and headaches.

Finally, if you’re environmentally-minded at all, you won’t find a more eco-friendly parking lot material than the permeable pavers from TRUEGRID. They are made from 100% post-consumer recycled plastic, and every step along the way is optimized for maximum environmental friendliness.

From production methods through installation, these grids are the easiest to install, most cost-effective, and the smallest negative impact of any parking lot material out there. The TRUEGRID system actually has a positive effect on helping filter pollutants. TRUEGRID pavers are the number one choice for maintaining a gravel parking lot successfully for many years. Learn more about our product lineup here.