Balancing project requirements and environmental concerns are becoming more important with every new project, particularly where heavy-duty pavement is required to manage high traffic and heavy loads. For modern heavy-duty pavement design and construction, TRUEGRID PRO PLUS commercial permeable pavers balance all of these factors with ease.

Traditional Heavy-Duty Paving Options vs. Natural Ground Cover

Natural ground cover is typically several layers of soils of varying permeability, held in place by plant growth. It is naturally a great rainwater retention system, preventing excessive runoff, erosion, and contamination as it absorbs rainfall. Thus, rainwater replenishes aquifers and gradually makes its way to streams, rivers, lakes, and oceans. Since natural ground cover doesn’t absorb much heat, surface temperatures will remain relatively cooler.

Breaking ground for driveways, parking areas, and commercial or industrial staging areas disturbs this natural protective layer. For decades, heavy-duty pavement options were limited to impermeable materials such as asphalt, concrete, or pavers. While these heavy-duty paving materials adequately manage heavy loads and high traffic, they are a major problem for the environment.

- Runoff from impermeable road surfaces leads to flooding, erosion, and contamination of streams and rivers.

- Impermeable surfaces prevent rain from absorbing into the ground where it could replenish groundwater and aquifers.

- Detention ponds and runoff retention areas can be built into the site to offset environmental hazards but take up valuable square footage and may be undesirable from a design standpoint.

- Inadequate grading or poorly designed runoff areas or retention ponds can hold stagnant water, the perfect breeding area for undesirable insects such as mosquitos and flies.

- Because asphalt and concrete absorb heat, local temperatures are relatively higher.

Permeable surfaces, such as gravel and turf, are better for the environment and don’t require additional detention or retention areas. Unfortunately, unstabilized turf and gravel can’t manage heavy loads or high traffic for very long, even if properly built-up – permeable concrete and porous asphalt pavements are both unacceptable in heavy-duty pavement applications. Gravel and turf areas may at first function like natural ground cover, but compaction due to heavy loads and high traffic eventually eliminates these benefits. Turf and gravel parking areas and driveways inevitably lead ruts, puddles, mud, bumps, and high maintenance costs, leading to some of the very same problems as impermeable surfaces.

Heavy-Duty Paving Solutions with TRUEGRID PRO PLUS Permeable Pavers

TRUEGRID PRO PLUS Permeable Pavers is one of the best heavy-duty pavement solutions, balancing your commercial heavy-duty pavement needs with environmental protection constraints and aesthetic design demands. Made of 100 percent post-consumer recycled high-density polyethylene, TRUEGRID PRO PLUS Permeable Pavers are environmentally friendly, lightweight, and easy to install. Once installed and filled, they can handle up to H-20 and HS-20 loading, for installation in parking areas, high traffic zones, equipment yards, construction site entrances, storage lots, and other heavy-use areas. They are ADA compliant. Every project is slightly different, but every heavy-duty paver installation requires three main elements for load bearing, traffic wearing, and environmental protection.

- First, subgrade preparations set the slope and depth of the final load bearing surface, allowing for at least 8 inches of sub-base and 2 inches of PRO Plus Permeable Paver grid – increase the depth of the sub-base to allow for higher loads or more water retention. Permeable or semipermeable geotextiles may be necessary between the sub-base and subgrade.

- Second, select the appropriate sub-base material. For gravel surfaces and best permeability, 3/4- to 1-inch angular gravel or Class 2 road base are excellent options. For grass surfaces, a 60/40 gravel/sandy-soil mix is recommended. After leveling, TRUEGRID PRO PLUS Permeable Paver grids are laid out, interlocking with each other across the entire paving surface. Trim edges and around obstacles with a saw.

- Finally, after tamping, fill TRUEGRID PRO PLUS Permeable Paver grids with the medium of choice. Angular or round gravel, 5/8- to 3/4-inch, allows for high permeability and extreme loading. Gravel/sandy-soil 60/40 mix is typical for grass seeding. Grass sod can be pressed into the grid for high traffic areas or laid on top for low traffic areas, both methods being suitable for heavy loads.

Heavy-Duty Pavement Design with TRUEGRID PRO PLUS Permeable Pavers

Because TRUEGRID PRO PLUS Permeable Pavers are 100 percent permeable and infinitely customizable, they can be used in many ways. Primarily, because water detention is built into the sub-base, TRUEGRID PRO PLUS Permeable Pavers eliminate the need for water detention ponds or runoff areas. This reduces construction and maintenance costs and frees up valuable square footage for better use. Once installed, TRUEGRID PRO PLUS Permeable Pavers require near-zero maintenance and lasts over 20 years. LEED Credit opportunities include stormwater management, recycled content, innovation & design, materials & resources, and heat island effect.

Aside from choosing your own fill, TRUEGRID PRO PLUS Permeable Pavers offer several customization options for your heavy-duty pavement design:

- TRUEGRID DECO can be used alongside PRO PLUS-equipped driveways and parking lots to delineate walkways or casual areas.

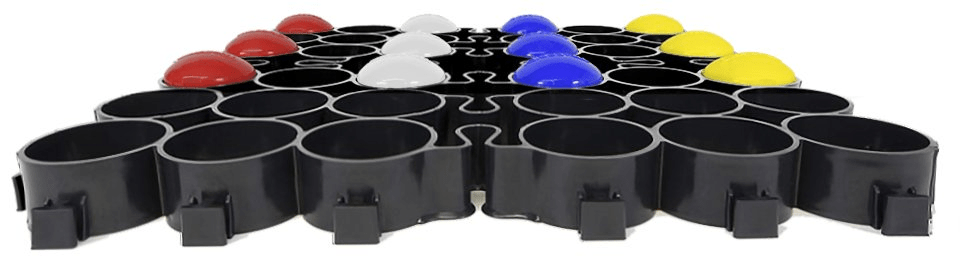

- TRUEGRID SuperSpot Reflectors and High Visibility SuperSpot parking markers snap into PRO PLUS pavers before filling to mark parking spaces, walkways, fire lanes, or direct traffic. No painting required!

- TRUEGRID PLATES can be used to number parking spots, handicap parking, fire lanes, no parking zones, or anything your project requires. No painting needed!

If you’re breaking ground on a construction or renovation project and need permeable ground cover for high traffic and heavy loads, contact TRUEGRID for an expert consultation and customization for your TRUEGRID PRO PLUS Permeable Paver system.